Managing Sudden Demand Spikes:

Scaling Challenges in Manufacturing

Sourcing flexibility is crucial for supply chain performance. A study of 336 companies from Europe and the U.S. found that companies with either low or high levels of sourcing flexibility exhibit high supply chain performance, whereas medium levels reduce performance by up to 30%. – Industry Science

The Viral Moment: When Success Feels Like a Supply Chain Nightmare

Your product just went viral. Orders are flooding in. Social media is on fire. The CEO is popping champagne. Great news – until someone points out the factory can only ship half of what’s been sold. The hype is real, but it also has a half-life. If you can’t scale fast enough, your “moment” becomes a missed opportunity.

So, what’s the strategy to turn that rush of demand into sustainable success? Let’s walk through the process, step by step, before the hype dies and customers moves on.

Step 1 – Managing Supply Chain Under Pressure

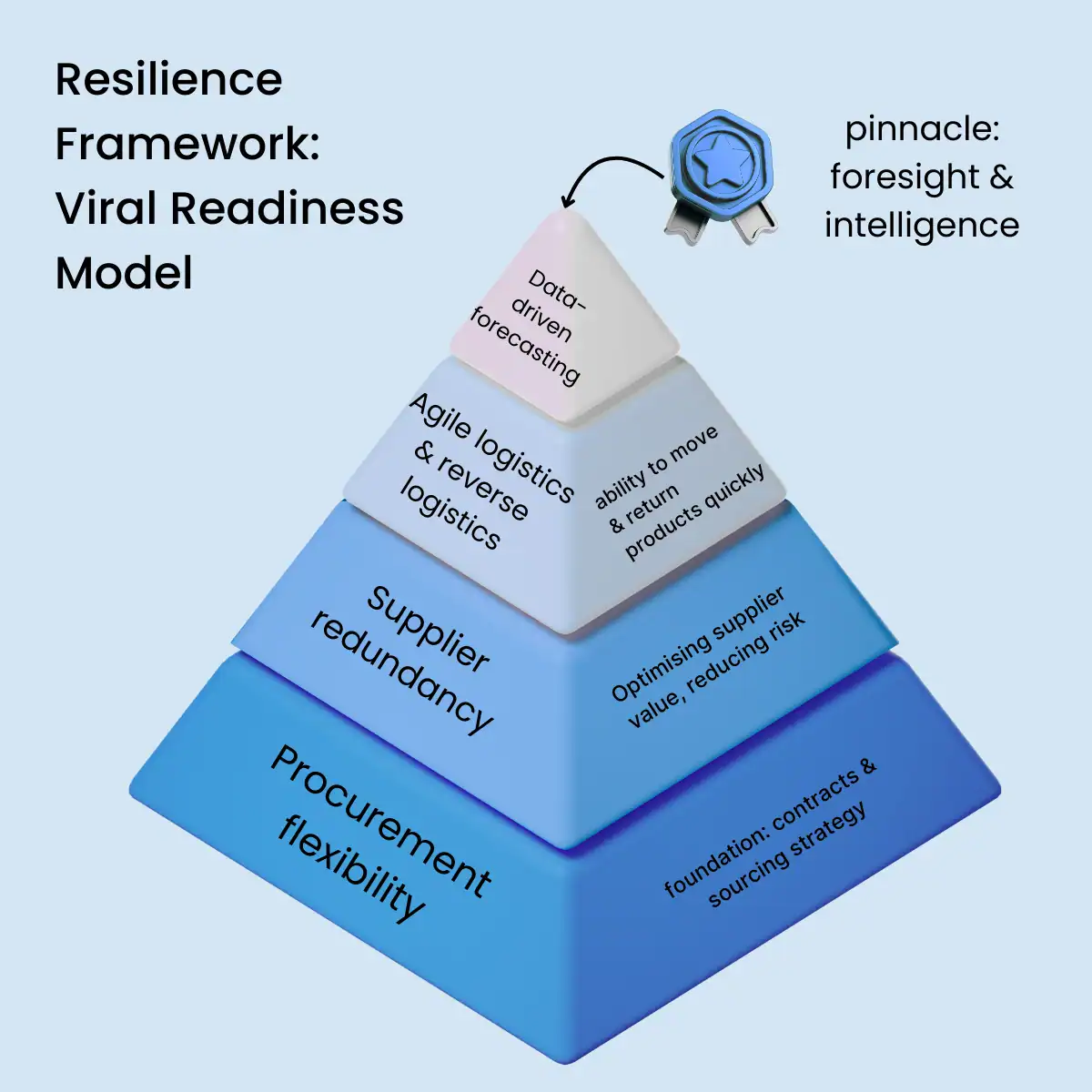

Sudden demand doesn’t just stress a supplier. It shakes the whole system. Raw materials get stuck upstream. Production queues back up. Distribution turns into a knife fight for warehouse space. This is where managing supply chain resilience matters most.

Think of it like plumbing: one blocked pipe and the whole network floods. The smart move is spotting those weak nodes early, before they burst.

Many supply chains are perfectly suited to the needs that the business had 20 years ago. – Michael Dell, Founder and CEO of Dell Technologie

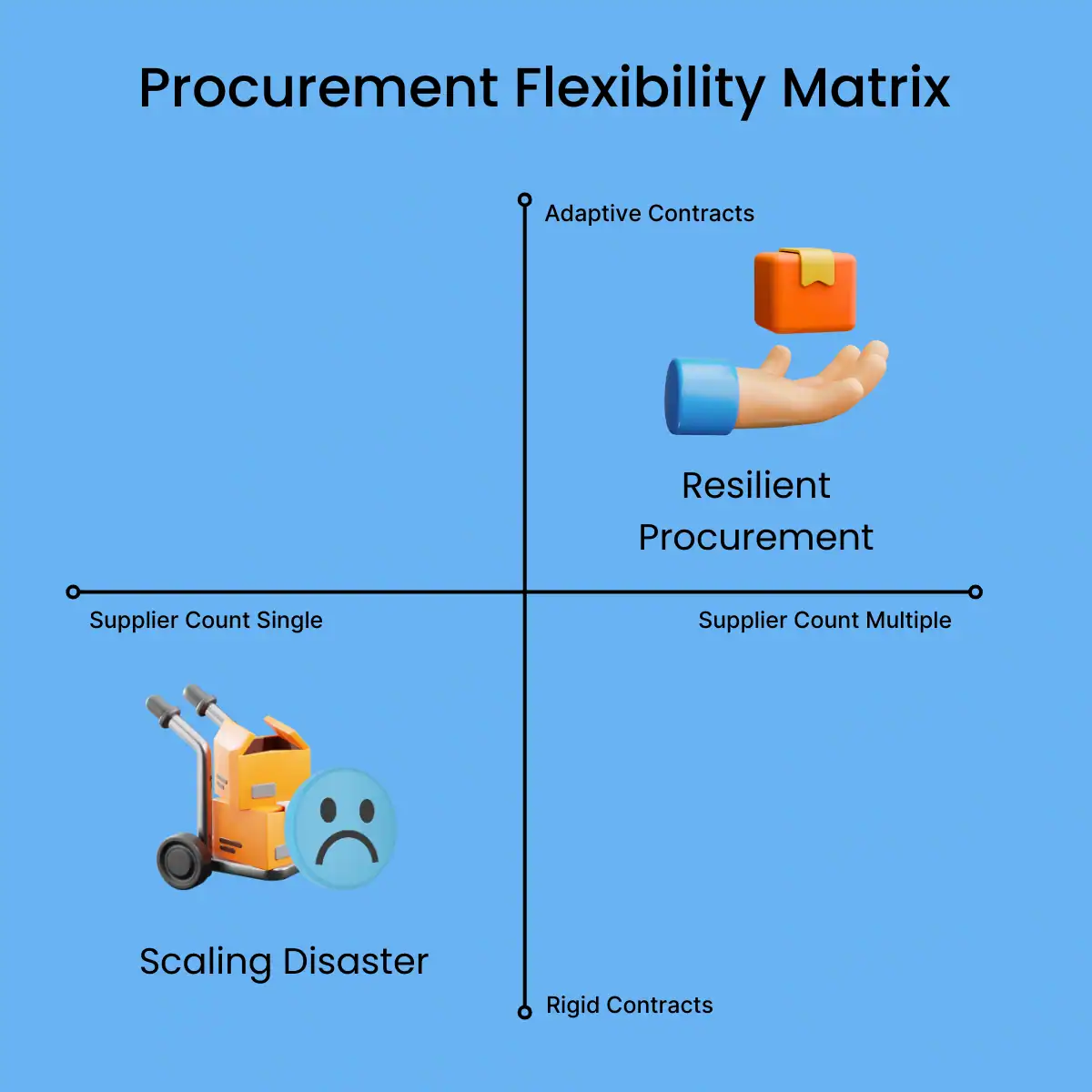

Step 2 – Procurement Strategy: The Overlooked Part of SCM

Procurement isn’t glamorous, but it’s the part of SCM that quietly makes or breaks scaling. If your supplier contracts don’t have surge clauses, you’re negotiating from a position of panic and that usually means higher costs or flat-out “NO.”

The fix? Build flexibility into contracts. Work with multiple suppliers. Keep a contingency plan in your back pocket. Procurement pros know that preparing for the “what if” is the difference between scrambling and scaling.

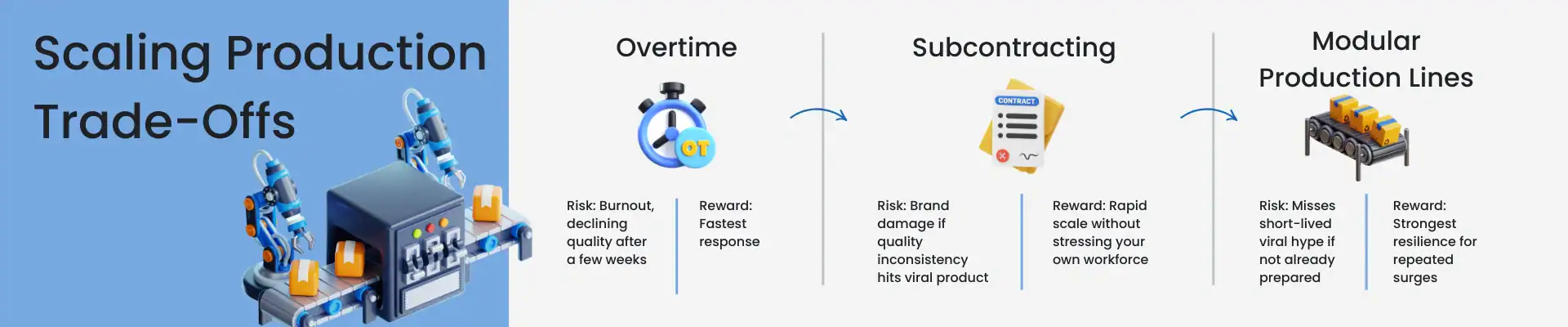

Step 3 – Manufacturing: SCM Control in Action

Now to the factory floor. Scaling production is about SCM control under stress. Sure, you can throw overtime at the problem, but that’s a short-term band-aid. Subcontracting or modular production lines buy you breathing space, but each option has trade-offs in speed, cost, and quality.

The golden rule: don’t compromise on quality just to meet volume. A viral hit can turn into a PR nightmare faster than you can say “product recall.”

Manufacturers with higher operational flexibility exhibited higher abnormal inventory growth, fewer employment reductions, and higher overall performance during major supply chain disruptions. – Science Direct

Step 4 – Logistics: The Fragile Logistic Chain

Even if you double production, it means nothing if the logistic chain can’t deliver. Trucks, ships, planes – they don’t magically appear when orders spike.

This is where inventory control in logistics becomes critical.

- Do you have the warehouse capacity?

- Can your 3PL partner flex?

- What about cross-docking to speed up turnaround?

Let’s also not forget reverse logistics – returns will rise along with sales, and a bad returns experience can kill brand loyalty just as fast as a stockout.

Step 5 – Data & Forecasting: Making the SCM Process Smarter

If your scaling strategy relies on gut instinct, you’re already behind. Demand spikes don’t come with a warning label, but data can at least give you a fighting chance.

Forecasting tools, real-time dashboards, and demand sensing tech make the SCM process more predictable. They help you spot a surge earlier, run “what if” simulations, and pressure-test your inventory chain before it collapses.

Call it supply chain fire drills – boring when things are calm, lifesaving when they’re not.

The real competition is between supply chains, not companies. – Martin Christopher, Professor Cranfield University

Step 6 – Learning from the Inventory Chain in Action

Take consumer electronics. A new smart device launches, and demand doubles overnight. The company that locked in extra supplier capacity months earlier? They scaled smoothly. The one that didn’t? Empty shelves, furious customers, and missed revenue.

The difference wasn’t luck. It was how they managed their inventory chain and whether procurement and logistics were prepared for the surge.

Resilient SCM in Practice

Scaling chaos isn’t avoidable – but it is manageable. The companies that survive viral demand aren’t the ones with the flashiest product. They’re the ones that built resilience into their supply chain, procurement, and logistics before the spike hit.

Going viral is luck. Surviving it? That’s strategy.

Explore more related content

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive Advantage

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive AdvantageSupply chain disruptions now...

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...