Digital Product Passports for Small Appliances & Air Purifiers:

A 2025–2027 Manufacturer Playbook

From the Oxera report: “DPPs in the EU are estimated to reduce compliance costs in consumer electronics by 15 %, equivalent to nearly €200 million of annual savings.

What is a Digital Product Passport? Why does it sound like you’re describing the next James Bond device? Ditch the spy drama. DPPs are less spy, more regulation + transparency. But they’re one of the most powerful tools in the product-maker’s toolbox, especially for small household appliances, consumer electronics, and air cleaners. Let’s break down what’s really going on, what the good companies are doing, and how you can lead, not follow.

What’s the Buzz: ESPR & DPPs in a Nutshell

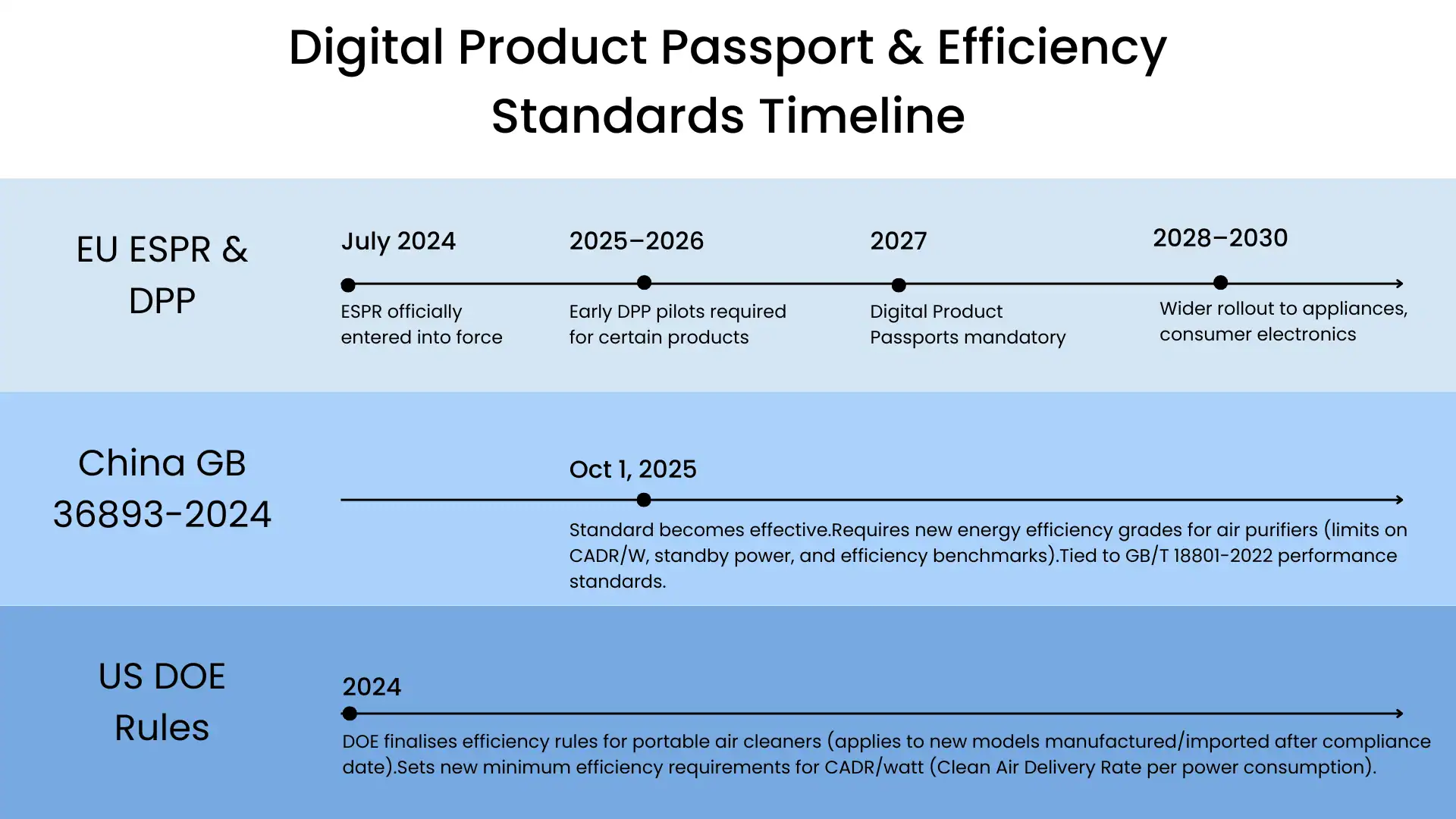

- The Ecodesign for Sustainable Products Regulation (ESPR) came into force on 18 July 2024, and is Europe’s new big stick + carrot approach to greener product design.

- One of its gems is the Digital Product Passport (DPP): an official, formalized product description of materials, components, performance, repairability, energy consumption, end-of-life treatment, etc. Imagine: product identity card, but for ecosystem footprint.

- DPPs aren’t accessories. They’re being associated with (or required by) delegated acts under ESPR for product categories. Some delegated rules are being drafted; others are on their way.

The Ecodesign for Sustainable Products Regulation (ESPR) … aims to significantly improve the sustainability of products placed on the EU market by improving their circularity, energy performance, recyclability and durability.

Why Air Purifiers (and Small Appliances) Are Under the Microscope

New Chinese standards GB 36893-2024 (energy efficiency grades + limits for air purifiers) become mandatory 1 October 2025. These impose stricter power/consumption standards alongside performance.

In America, the DOE is updating energy efficiency standards for portable air cleaners (purifiers), effective 2024. Companies will have to perform above higher levels; customers will insist on it.

Consumers do care: “is it efficient?” is nearly as important as “does it clean air?”. Efficiency = energy cost, sustainability credentials, brand value. High-profile certifications (ENERGY STAR, DOE, etc.) are heavily weighted.

Putting the Pieces Together: DPP + Efficiency = New Design + Data Challenges

This is where engineering intersects compliance intersects data architecture. Working with Digital Product Passports and new efficiency needs as a systems issue not just a documentation issue, is what distinguishes winners from laggards.

Bill of Materials (BoM) and material data

In-depth disclosure of recycled content, chemical composition such as SVHC, and supplier traceability are required in DPPs. This would include the earlier auditing of your BoM during the design stage and prompting suppliers to provide validated raw data. Certain innovators go as far as testing blockchain-style proofs to validate data.

Energy performance

Air purifiers and appliances are not only being tested by how they perform but also their efficiency. Filter pressure drop, fan efficiency, and standby power are now the measurements of focus. Forward-thinking companies are simulating energy usage further ahead in the design process, designing lower-resistance filters, and using modular firmware modes to facilitate power optimization.

Textiles and Footwear, Electronics and ICT are among the first sectors to be hit by the DPP rollout, product categories with complex supply chains, multiple materials, and strong regulatory/trend pressure.

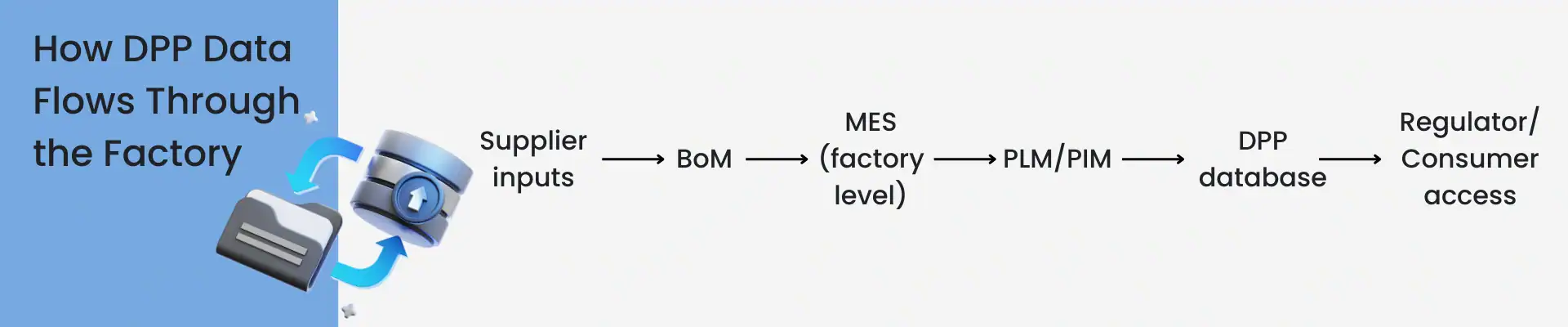

Label / UID / Product Identity

Every characteristic needs to be marked with a specific identifier, typically a UID or QR code associated with the approved DPP. This means investment in serialisation on these factory floors and having Manufacturing Execution Systems (MES) that can acquire and transmit identity information natively into Product Lifecycle Management (PLM) and Product Information Management (PIM) systems.

Data System & Hosting

The data systems themselves are another frontier. The DPP data model needs to be stored, validated, and made accessible to regulators and in certain cases consumers. Many manufacturers are experimenting with JSON or CSV data formats, others are experimenting with decentralised identifiers (DIDs) and verifiable credentials to create a scalable, tamper-proof data ecosystem. Harmonisation with GS1 standards is crucial to enable interoperability across global supply chains.

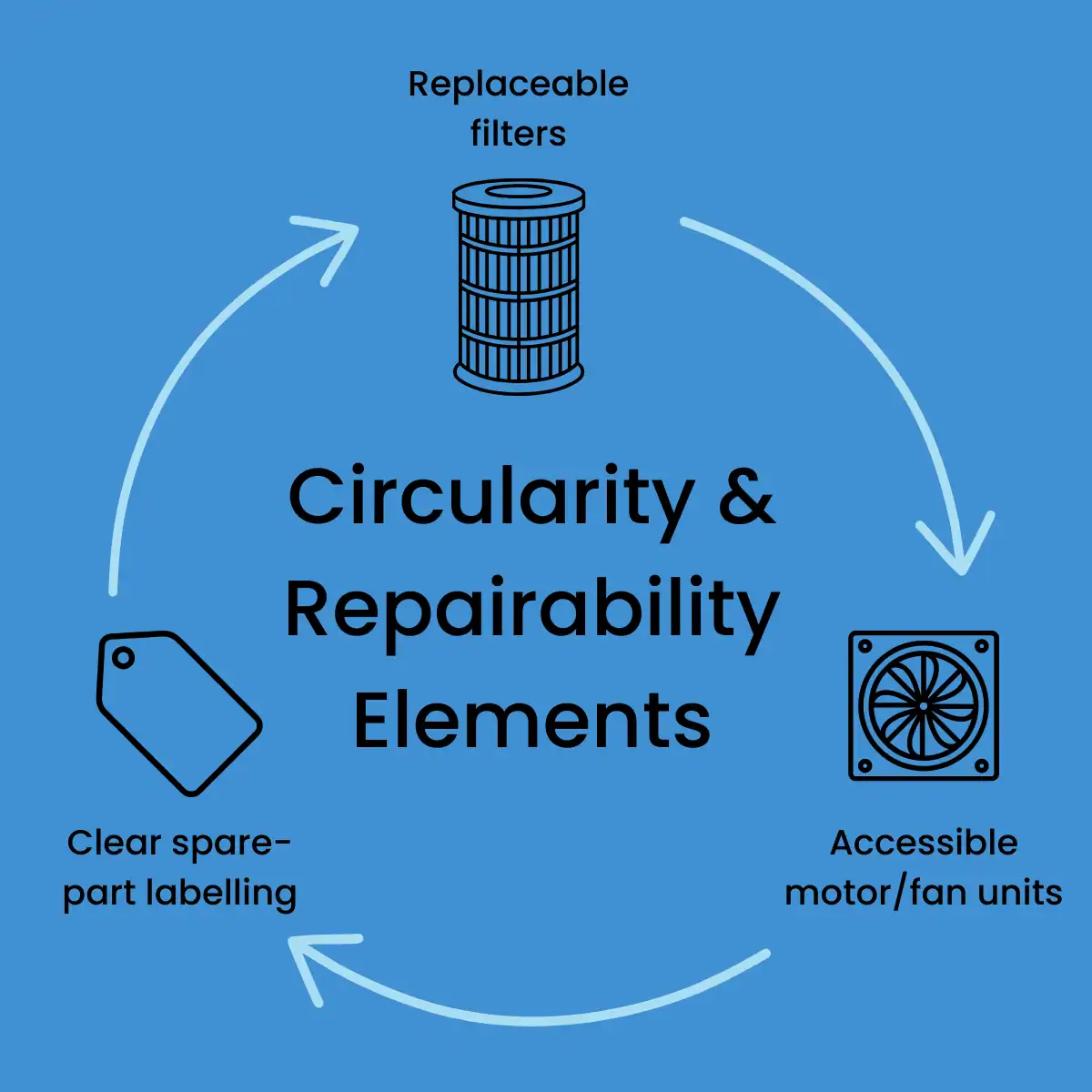

Circularity and Repairability

This can no longer be an afterthought. Legislation must accommodate provision for easy tear-down instructions, availability of spare parts, and transparency around end-of-life handling. Market leaders are responding by product redesign for easy tear down, spare-part availability commitments spanning decades, and even developing digital repair guides that can be accessed directly from QR-coded DPPs.

In brief, compliance today is about marrying engineering discipline, supply-chain visibility, and digital traceability. And those who design these principles into products from the outset can remain ahead more easily and at lower cost.

The DPP is the tool that will digitally and traceably communicate this information across the value chain.

Strategic Moves: What Makes a Manufacturer Look Like a Leader (vs Just “Compliant”)

Because merely being compliant is the bare minimum. Winning looks like:

Pilot early, across one SKU or product line

Take a product that is already mature (e.g. a top-selling air purifier model) and run it through DPP data capture, UID implementation, energy efficiency testing, repair transparency. Iron out the wrinkles before rolling across entire lines.

Integrate DPP design into product development (not tacked on at the end)

R&D / design engineering needs to design for circularity, energy efficiency, data transparency from Day 1. Design changes late in the game are expensive.

Choose flexible data architecture/tools

PLM (Product Lifecycle Management), PIM (Product Information Management), MES (Manufacturing Execution Systems) need to be able to capture, store, validate, and traffic the relevant DPP fields. Interoperability needs to be considered as well: GS1, traceability standards, possibly decentralized identity (DID) solutions, verifiable credentials.

Global-regulatory alignment is the target, but local implementation

Since ESPR is EU, but similar energy efficiency / air quality / environmental product legislation is emerging globally (e.g. China, U.S.), design to the highest common denominator where feasible, or develop product variations as necessary. Modular designs or firmware toggle-modes for energy settings are worth consideration.

Storytelling & transparency as differentiator

Once you have the data, let the world see it: sustainability reports, consumer QR-codes, marketing that explains “why our purifier uses 30% less energy in standby, or has certified parts availability for 10 years.” These are differentiations that can command premium or at least reduce price pressure.

The transition to a circular economy is a key pillar of the European Green Deal. The necessary view on the entire product life cycle requires knowledge of both the upstream stages and the effects of one’s own actions on downstream stages of the value chain. – German Economic Institute, 2025

Hurdles (Yes, There Are Some) & How To Jump Them

Data capture/supplier alignment: Not all upstream suppliers track the level of detail that you need (materials, chemical content, etc.). Involves supplier audit or agreements.

Cost & tooling: Printing UIDs/QRs, re-designing MES/PLM, meeting grade limits can entail up-front cost. Must be planned for early.

Standardization uncertainty: Some of the delegated acts (ESPR) are still to be finalized for specific product groups. So there’s risk of rework.

Balancing regulation vs consumer usability: DPPs must be detailed, yet too much information presented to consumers (complex, technical) will confuse instead of convince. Thus, you need both machine-readable + consumer-friendly layers.

What Industry Leaders Are Saying & Doing

The requirements for DPPs encompass all product categories identified by the EU via delegated acts; where relevant, these cover both locally manufactured and imported products.

- Intertek has published a number of guides: companies are being urged to prepare now, particularly textiles and consumer electronics, as part of compulsory roll-out starting ~2027.

- Academic research (e.g. via arXiv) is exploring the use of Decentralised Identifiers (DIDs) + Verifiable Credentials for managing DPPs in a scalable, robust way.

- In the US, new DOE efficiency standards for air purifiers will see consumers requiring less energy usage in the near future, and the government will be mandating it.

The global digital product passport market was valued at USD 183 million in 2024 and is expected to grow at a CAGR of 22.6 % between 2025 and 2034, reaching around USD 1.4 billion by 2034.

Action Plan: What You Should Be Doing Now

- Pick one or two high-volume products (e.g. air purifiers, small kitchen appliances) and build a “DPP pilot kit”: all relevant material/BOM data, supplier data, energy performance, UID serialization.

- Audit your current product architecture for energy inefficiencies: motors, fans, standby modes, filter pressure drop. Rank-order engineering improvements for best efficiency return per dollar.

- Ensure your manufacturing / operations stack can produce UID/QR/identification at scale and transmit it onwards to digital systems (MES, PLM).

- Define your data model: format (JSON/CSV/XML), fields needed (material composition, energy use, repairability, etc.), digital hosting infrastructure, permissions and access (regulators, consumers).

Train your teams (design, regulatory, supply chain) so all know what data is needed and when. Have supplier agreements in place to deliver upstream compliance for data. - Create marketing & labeling strategy that leverages the DPP and energy credentials as a differentiator.

Final Thought: The Punch

Here’s the deal: DPP + air purifier / appliance efficiency regulation isn’t just another compliance hoop. It is a chance to make improved products and trust. Those who do it as paperwork will lose; those who do it as product innovation will win.

So, get your BoM audits done, data architecture established, and your narrative straight. For soon, “regulation-ready” will be table stakes, and “transparent, efficient, repairable” will be the competitive advantage of the future.

Explore more related content

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive Advantage

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive AdvantageSupply chain disruptions now...

Why Air Quality Devices Are the Fastest-Growing Smart Home Category in 2025

Why Air Quality Devices Are the Fastest-Growing Smart Home Category in 2025H6: “96% of Europe’s urban population is...

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...