INTRETECH HUNGARY

– Your European Hub for Smart Manufacturing

From design and tooling to assembly, testing, and reverse logistics—right at the heart of Europe.

ISO Certifications:

9001 / 14001 / 27001 / 28000

IATF 16949

33,500m² of

manufacturing space

On-site dormitories

for factory workers

IATF 16949:2016

Why Intretech Hungary?

Since launching production in 2019, our Kapuvár facility has brought Industry 4.0 technologies and created over 200 local jobs, establishing us as a reliable nearshoring hub for European markets.

- 73,500 m² planned total floorspace

- 33,500 m² dedicated to manufacturing

- 170,600 m² total land secured

- Onsite dormitories for workforce accommodation

As part of Intretech’s vertically integrated network, the site delivers full end-to-end solutions — from product design and tooling to mass production, testing, and logistics.

Full-Stack, Vertically Integrated Manufacturing

From initial tooling and precision molding to PCBA, assembly, testing, packaging, warehousing, and even reverse logistics—we manage every step in-house. Our high-speed SMT lines in ISO8 clean rooms, automated soldering and wave processes, and UMS-powered traceability enable unmatched quality, efficiency, and responsiveness.

m2 Electronics + Assembly

m2 Assembly

m2 Injection + Paint + Metal

m2 Assembly + Logistics

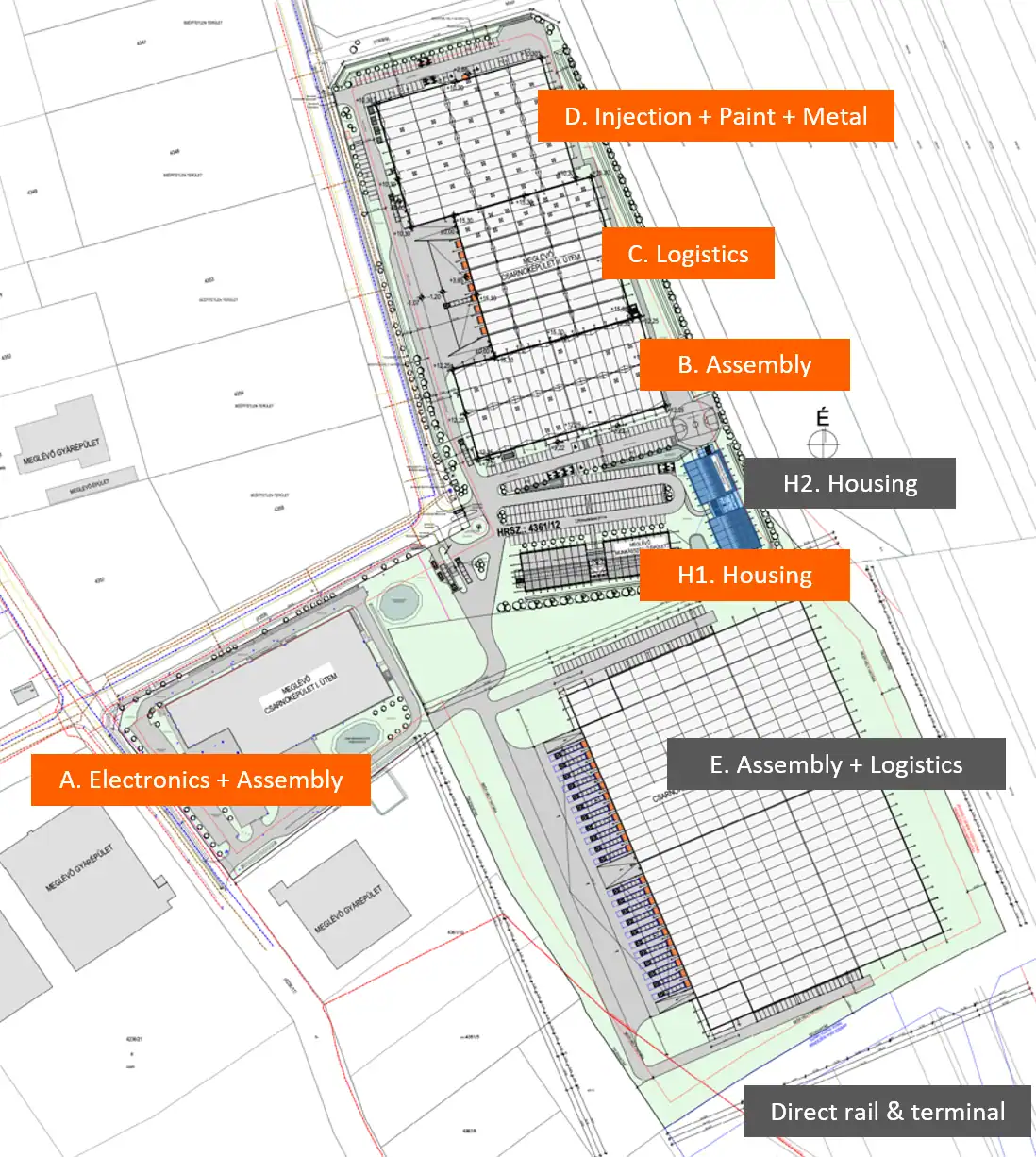

Production Site Overview

Our Kapuvár facility combines modern infrastructure with future-ready expansion.

- Electronics + Assembly – 7,500 m² (completed)

- Assembly – 10,000 m² (completed)

- Logistics – 5,800 m² (completed)

- Injection + Paint + Metal – 6,700 m² (completed)

- Assembly + Logistics – 36,000 m² (planned Q3 2025)

- Housing 1 – 3,000 m² for 200 people (completed)

- Housing 2 – 4,500 m² for 350 people (planned Q2 2026)

- Direct rail & terminal connection – planned Q4 2026

Core Processes

Our Hungary site integrates all major production processes under one roof:

SMT + Wave Soldering

- ISO8 cleanroom (650 m²)

- Panasonic double pathway, SPI + AOI inspection, reflow and through-hole soldering

Injection Molding

- 4,000 m², 10 electric machines (+30 planned)

- 190t–700t capacity (scalable up to 2000t)

- Painting line planned

Assembly

- 32,000 m², ISO9 environment

- 20+ lines with ESD flooring

- Automated soldering, gluing, and testing systems

Metal Processing

- 2,500 m²

- CNC, WEDM, laser cutting, grinding, drilling, milling, welding, foaming

Testing Lab

- Thermal shock chamber, salt spray, drop, shake, ESD, carton compression

- Full lifecycle testing (aging room 40–60 °C)

Assembly

- 32,000 m², ISO9 environment

- 20+ lines with ESD flooring

- Automated soldering, gluing, and testing systems

Warehouse

- 26,000 m²

- 15,000 EUR pallets, 35 loading docks

Certifications & Quality Excellence

Intretech Hungary combines advanced production capabilities with internationally recognized quality standards.

- ISO 9001, 14001, 27001, 28000, IATF 16949 certified

- MES-connected workflows with full traceability

- ESD-safe environments and first-time-right manufacturing

- Fully electric injection molding lines, advanced tooling & painting

- Metal processing (CNC, stamping, die-casting)

Comprehensive lifecycle and automated testing

This ensures reliable, scalable, and compliant manufacturing that meets the strictest industry demands.

European Advantage: Strategic Location, Global Quality

Located strategically in western Hungary, Intretech Hungary enables efficient nearshoring for European brands seeking reduced logistics complexity and cost. We combine global best practices with local insight—ideal for automotive, consumer electronics, medical, IoT, and industrial clients.

- Reduced logistics complexity and cost with central European location

- Fast reaction and shorter lead times compared to overseas production

- Local workforce supported by modern onsite housing and infrastructure

- Direct rail terminal (planned 2026) for seamless supply chain integration

Serving Global Industries

From Kapuvár, we support global brands across multiple sectors. Our Hungarian operations are designed for fast prototype-to-production ramp-up and powered by a strong automation and smart manufacturing culture—making us the reliable nearshoring choice for Europe.

Automotive

High-precision tools for complex components that meet rigorous performance standards.

Consumer Electronics

Sleek, innovative designs supported by tools engineered for perfection.

Medical

Energy & Industrial

Home Appliances

Manufacturing efficiency and quality solutions tailored for everyday consumer products.

Our clients include leading international companies who rely on us for speed, quality, and scalable growth.

Partner with Intretech Hungary

Bring your innovations to market faster, smarter, and closer to your customers.

Explore more related content

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive Advantage

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive AdvantageSupply chain disruptions now...

Agentic AI in Manufacturing: Why 2026 Is the Year AI Finally Starts Doing the Work

Agentic AI in Manufacturing: Why 2026 Is the Year AI Finally Starts Doing the WorkThe global AI in manufacturing...

Why Air Quality Devices Are the Fastest-Growing Smart Home Category in 2025

Why Air Quality Devices Are the Fastest-Growing Smart Home Category in 2025H6: “96% of Europe’s urban population is...