OEM Automotive in 2025:

Buckle Up, Procurement and Logistics – It’s a Wild Ride

If Henry Ford walked into a modern OEM plant, he wouldn’t recognise the industry he revolutionised.

So, let’s cut through the noise and talk about how to survive and thrive, in this shifting landscape.

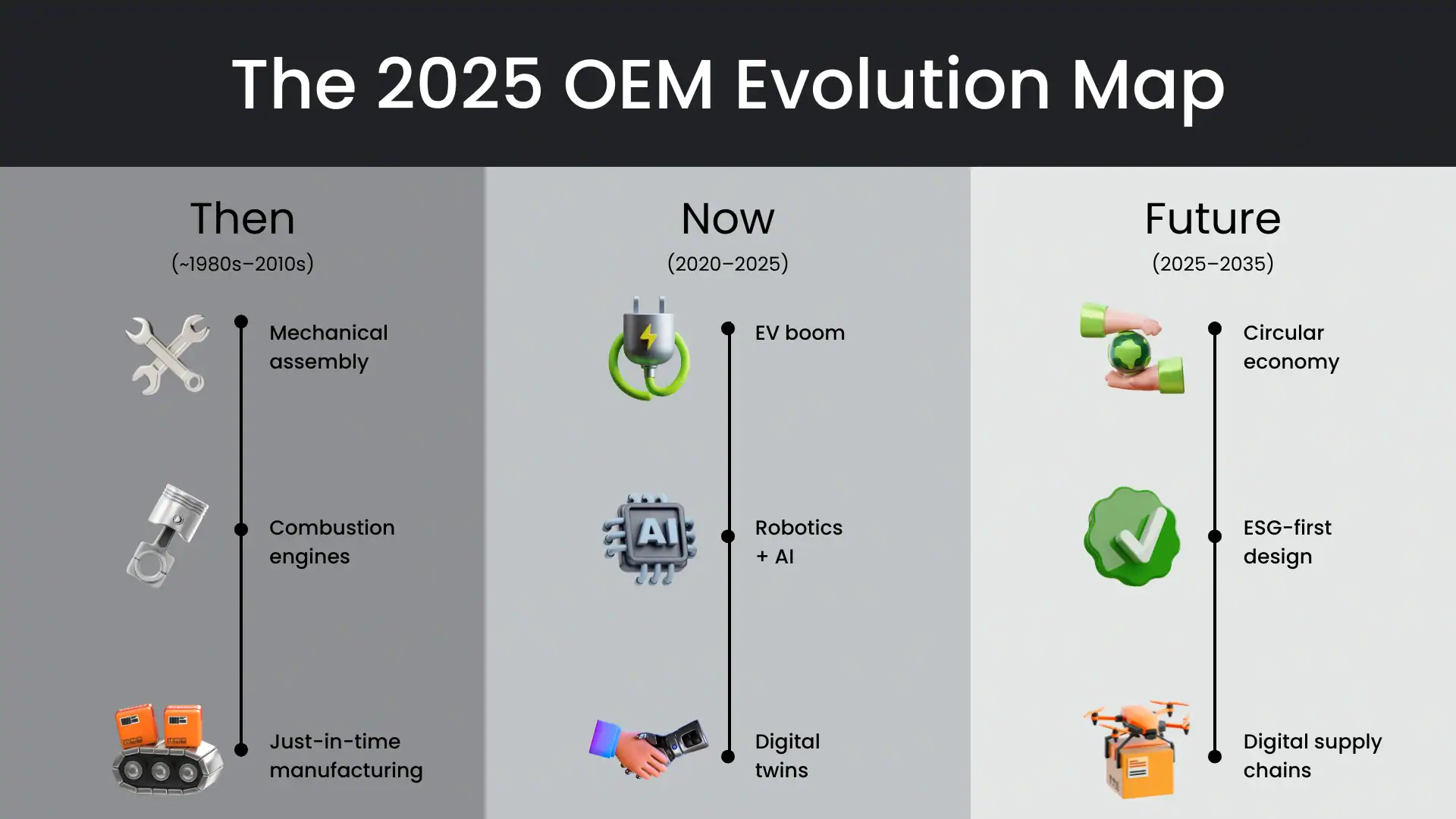

The New Face of OEM Automotive Manufacturing

Once upon a time, OEMs just bolted together steel and rubber. Not anymore.

- Advanced robotics, AI, and digital twins are running the show on factory floors.

- EV sales are blasting off, rewriting component designs and triggering a mad scramble for batteries, rare earths, and electronics.

- Self-driving and connected vehicles are transforming OEMs into software companies, complete with all the cyber headaches that come with it.

- And just to keep things interesting, geopolitics is sending everyone back to the drawing board on where to build stuff, thanks to regional trade spats and new compliance rules.

Bottom line: OEM manufacturing today is part high-tech lab, part geopolitical chess match.

“By 2026, 80% of procurement leaders will invest in AI-based sourcing tools” – Gartner

Procurement’s Tightrope Act

(Challenges and Opportunities)

If you’re in procurement, welcome to your new juggling routine. Your challenges? Oh, just a few minor ones:

- Chasing critical materials like lithium, cobalt, and semiconductors.

- Balancing costs pressures with sustainability targets.

- Managing a supplier roster of software and technology suppliers alongside traditional parts vendors.

But hey, there’s opportunity hiding in the chaos. Think strategic supplier alliances, nearshoring to reduce risk, and digital procurement tools like blockchain for transparency or AI for smarter sourcing.

One more thing: if your suppliers can’t spell “sustainability,” you’re already behind.

Logistics: From Just-in-Time to Just-in-Case

Logistics pros, it’s time to rethink your life choices – or at least your operating model.

- Batteries now rule the roost, and they’re a regulatory nightmare to transport.

- Just-in-time is getting swapped for just-in-case, with buffer stocks for critical parts so factories don’t grind to a halt when a ship gets stuck in the Suez.

- Tech is your new best friend. IoT sensors, digital twins for logistics, and autonomous delivery vehicles are changing how stuff moves, giving you real-time visibility and the power to predict (instead of panic).

Translation: logistics is no longer about trucks and ships. It’s about data, foresight, and not getting blindsided.

81% of consumers say sustainability influences their car brand preference.

— Capgemini Research Institute

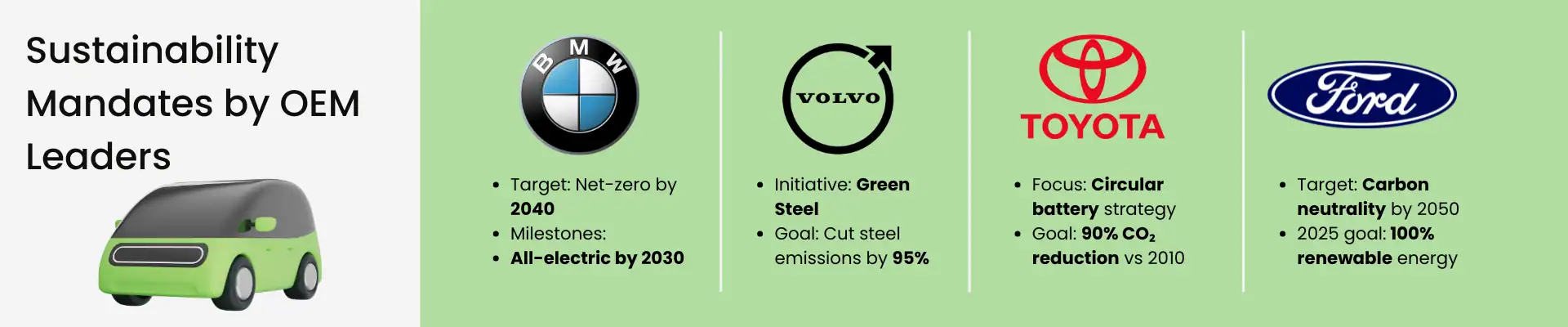

Sustainability: Always a Must

OEMs are under regulatory and consumer pressure to reduce carbon emissions, minimise waste, and increase the recyclability of components.

Logistics and procurement teams have new marching orders:

- Selecting suppliers with robust sustainability practices. (greenwashing won’t cut it).

- Design logistics networks with a carbon calculator in hand.

- Implementing circular economy practices, such as recycling battery materials or remanufacturing parts.

OEMs like BMW and Volvo are already rolling out green steel and low-carbon aluminium. Everyone else better keep up, or risk getting labelled the industry boomer.

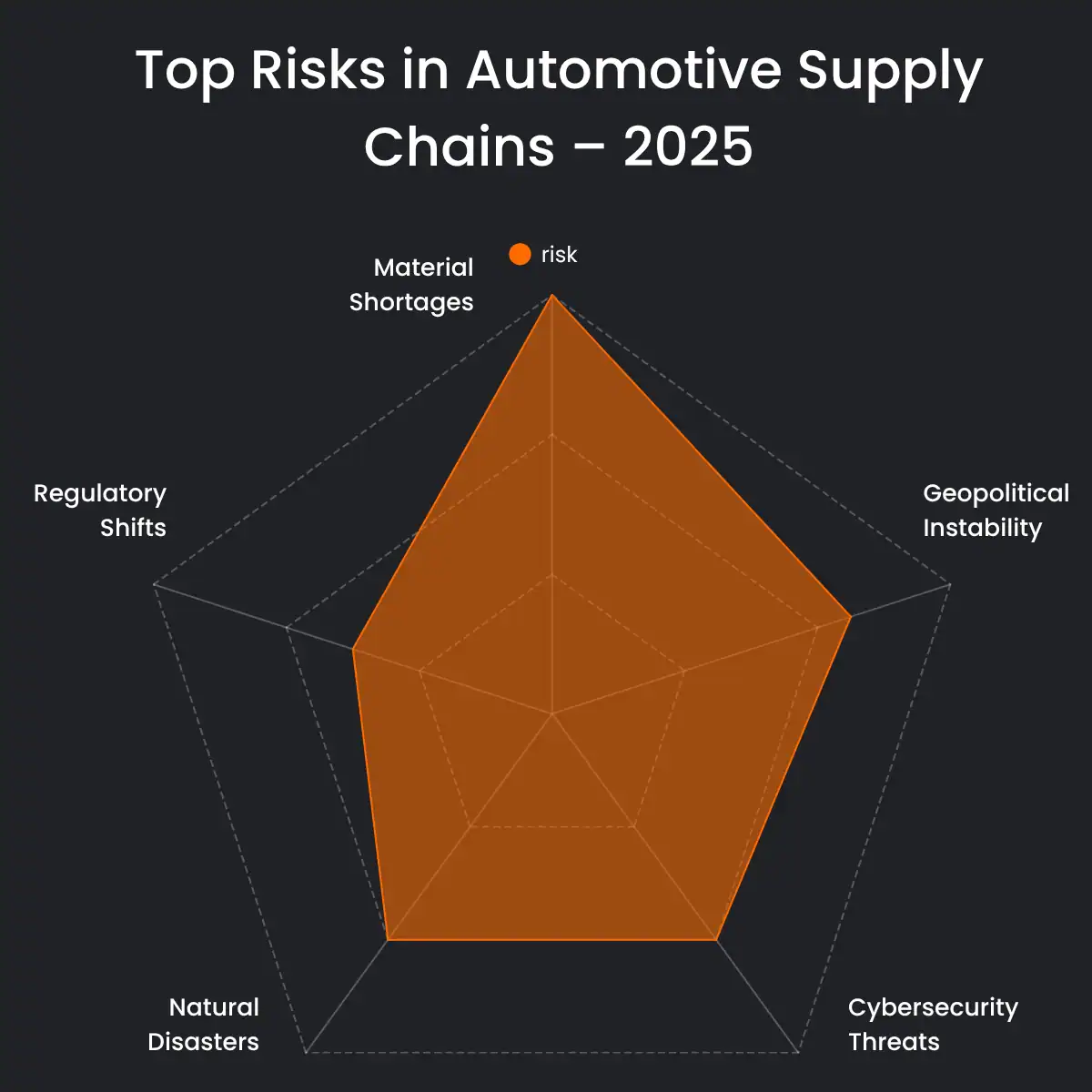

Risk: The New Business Constant

If you think supply chains have ever been stable, that’s adorable.

- Geopolitical instability threatens critical supply lines.

- Natural disasters and climate change disrupt global transport routes.

- Cyber threats increasingly target interconnected manufacturing systems.

The proactive risk management playbook now includes:

- Mapping your supplier risks like a crime board in a detective show.

- Dual sourcing to avoid putting all your eggs in one basket.

- Investing in digital tools that let you model worst-case scenarios and respond before your CFO starts hyperventilating.

Visibility is and will forever be your best friend.

“The car of the future won’t just be built differently — it will be imagined, engineered, and delivered in ways the old industry never saw coming.”s

What’s Next in OEM Automotive Manufacturing? Buckle Up

Here’s what’s rapidly approaching on the horizon:

- Solid-state batteries have the potential to fundamentally reshape the EV supply chain.

- ESG reporting requirements are set to become significantly stricter, with real consequences for non-compliance.

- Digital ecosystems will increasingly integrate OEMs, suppliers, and logistics partners, creating tighter interdependencies across the value chain.

So, logistics and procurement pros, here’s your survival kit:

- Embrace digital tools and advanced analytics to drive smarter decision-making.

- Cultivate strong, collaborative relationships with suppliers rather than relying solely on transactional interactions.

- Maintain the agility to adapt swiftly when unexpected challenges arise.

- And above all, treat sustainability as a strategic business driver, not merely a compliance exercise.

OEM automotive manufacturing in 2025 is demanding, volatile, and let’s admit it – kind of thrilling. For logistics and procurement teams, this is your moment to step up. Adapt fast, embrace the tech, and lead the charge on sustainability. Those who do will carve out serious competitive advantage. The rest? Well… like we said, buckle up.

Explore more related content

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...

Digital Product Passports for Small Appliances & Air Purifiers

Digital Product Passports for Small Appliances & Air Purifiers: A 2025–2027 Manufacturer Playbook From the Oxera...