3PL in Manufacturing: Outsource Your Logistics, Not Your Control

“Supply chains compete, not companies. And logistics is the front line.”— Martin Christopher, Logistics & Supply Chain Professor, Cranfield University

Logistics. Just the word sends shivers down procurement’s spine. Global supply chains tangled tighter than your average earbuds, demand swings like a mood ring, and warehouse space rarer than compliments from Finance. You’re constantly walking a tightrope between keeping control in-house (and potentially drowning in operational inefficiencies) or outsourcing and crossing your fingers.

Enter third-party logistics (3PL). Is this your logistics superhero, or a headache waiting to happen? Let’s get into it.

What Exactly is 3PL (And Why Should You Care)?

Simply put, 3PL involves outsourcing logistics operations – like warehousing, transportation, and distribution – to specialised providers. For manufacturing logistics, it covers everything from getting raw materials to your factory, to delivering spare parts, to managing warehouse management systems, to distributing finished products globally through comprehensive fulfillment services.

Think of 3PL providers as the Uber Eats of logistics – convenient until your shipment arrives late, cold, or completely wrong. Procurement teams need to care because logistics impacts costs, lead times, inventory management accuracy, and overall supply chain risk. You’re not just buying components; you’re buying reliability.

“The global 3PL market is projected to reach $1.75 trillion by 2027.”— Market Research Future, 2023 Report

When Does 3PL Actually Make Sense?

Outsourcing logistics isn’t just about convenience; it’s strategic supply chain management.

- Speed to Market: Rapidly scale logistics operations without huge upfront investments in warehouses or fleets.

- Flexibility: Easily meet demand surges without logistical nightmares through partnering with a 3PL provider.

- Global Reach: Expand internationally without reinventing your logistics wheel in every new region.

- Focus: Let your teams stick to their strengths – making great products, rather than chasing shipments.

Think about it: You wouldn’t build roads to deliver your products. Why manage freight lanes yourself?

Who Should Actually Be Using a 3PL?

Not everyone should jump on the 3PL bandwagon. If you:

- Struggle to manage bloated inventory.

- Can’t consistently meet customer SLAs.

- Are eyeing international markets.

- Find your ops team buried in logistics problems…

Then, congratulations – you’re the prime candidate.

But hold off if your logistics volumes are minimal, if your products require highly specialised handling, or if your in-house logistics team gives you a competitive advantage.

“Only 21% of organisations have end-to-end supply chain visibility.”— McKinsey & Company, 2023 Global Supply Chain Pulse

Now, the Dark Side of Outsourcing: 3PL’s Downsides

Before you run to sign that contract, consider these pitfalls:

- Lost Visibility: When someone else handles your logistics, transparency can drop faster than your patience during quarterly budget meetings.

- Misalignment Risks: Nobody knows your products as intimately as you do. Miscommunication is practically guaranteed at some point.

- Hidden Costs: Watch out for storage fees, minimum volume penalties, or surprise handling charges.

- Dependency Risks: Your supply chain resilience is now in their hands. Remember, outsourcing risk doesn’t eliminate it – it just shifts it.

3PL vs 4PL: Which One Should Procurement Choose?

Quick comparison:

- 3PL: Handles the physical logistics.

- 4PL: Manages your entire logistics ecosystem, including selecting and managing 3PLs.

3PL is the hands; 4PL is the brain. Ensure they aren’t operating off different maps, or chaos is inevitable.

“69% of manufacturers outsource at least part of their logistics function.”— Statista, Global Manufacturing Survey 2024

Who Are the Big logistics companies in the 3PL World?

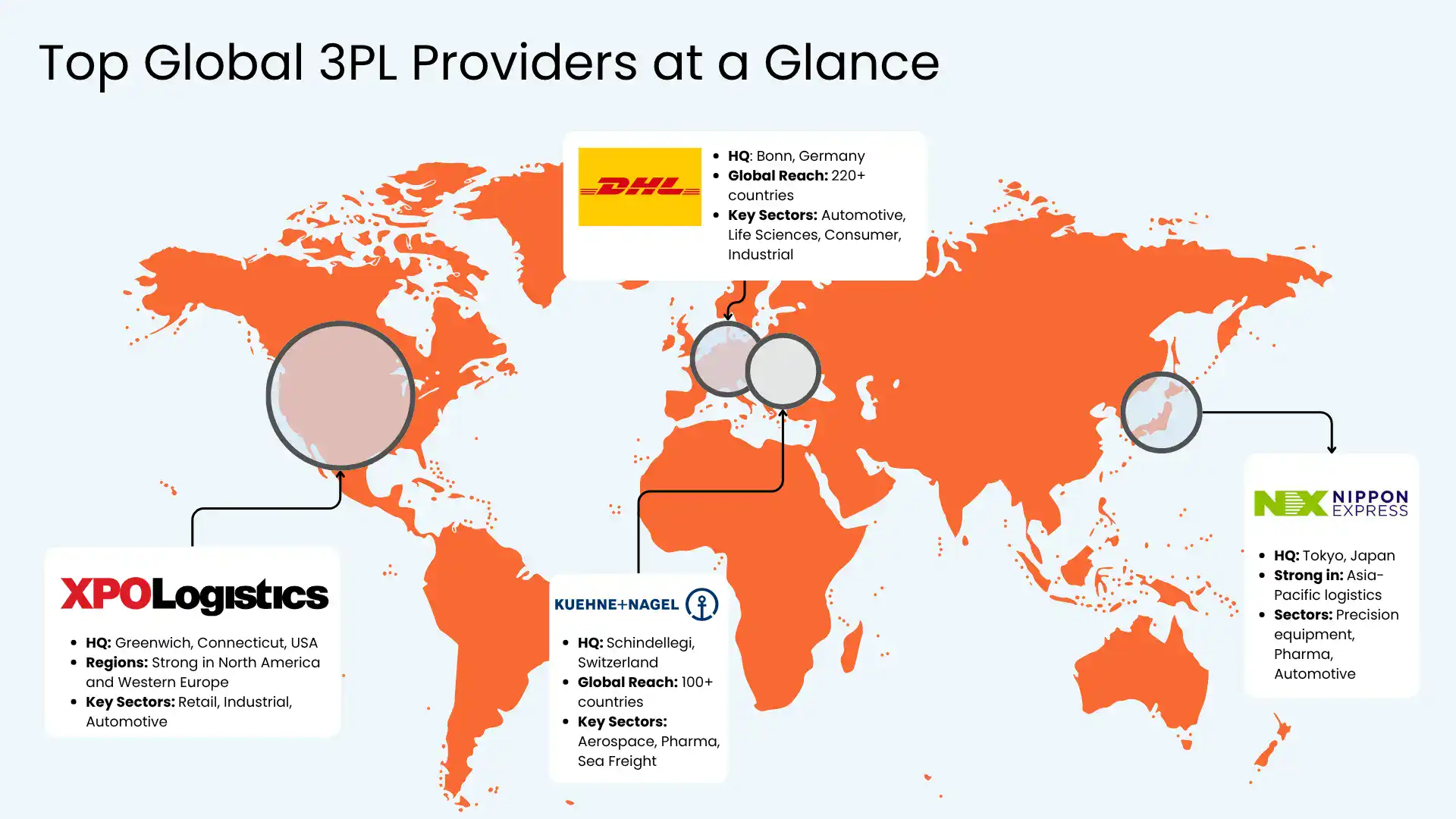

Familiar names dominate the landscape:

- DHL Supply Chain

- XPO Logistics

- DB Schenker

- Kuehne + Nagel

- GXO Logistics

But remember: bigger isn’t always better. Regional or niche 3PL providers might offer precisely the agility and tailored service your manufacturing operation needs.

Vetting a 3PL: Procurement’s Cheat Sheet

When evaluating potential partners, be ruthless:

- What’s their on-time delivery rate?

- How do they handle returns and damaged goods?

- Can they seamlessly integrate with your internal systems?

- How flexible are they during demand spikes?

Never compromise on tech or transparency. Ever.

“Your 3PL is either a growth multiplier — or your biggest bottleneck.”— Paul Keel, CEO of Smiths Group (ex-3M)

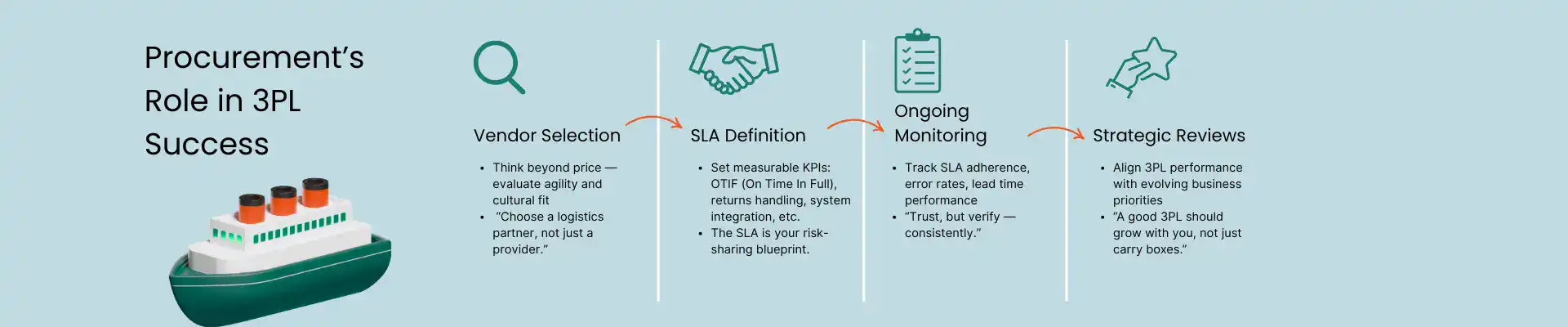

Procurement Makes or Breaks the 3PL Relationship

This isn’t just a logistics decision – it’s a strategic procurement one. If procurement treats 3PL as a “set-and-forget” black box, you’re setting yourself up for costly failures.

Smart procurement teams know how to pressure-test providers, set meaningful SLAs, and align their logistics strategy with broader business goals.

A good 3PL can make procurement look brilliant. A bad one? Let’s just say you’ll know exactly what the board wants to discuss next quarter.

Explore more related content

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...

Digital Product Passports for Small Appliances & Air Purifiers

Digital Product Passports for Small Appliances & Air Purifiers: A 2025–2027 Manufacturer Playbook From the Oxera...