Sustainable Procurement Strategies: Aligning ESG Goals with Profit

Procurement isn’t just about getting the best price anymore. It’s about buying smarter, greener, and for the future.

Procurement pros, supply chain warriors — let’s be honest. Balancing profit margins with ESG (Environmental, Social, and Governance) goals feels a lot like juggling flaming swords while riding a unicycle. Thrilling? Sure. But easy? Not so much.

Especially in electronics and smart manufacturing, where the pressure to innovate, stay sustainable, and protect the bottom line is hotter than a newly soldered PCB. So the million-dollar (or maybe billion-dollar) question is: can procurement actually find that sweet spot between financial performance and ESG goals? Spoiler alert: absolutely — if you play your chips smartly.

Let’s dive into how.

Why Procurement Holds the Golden Key

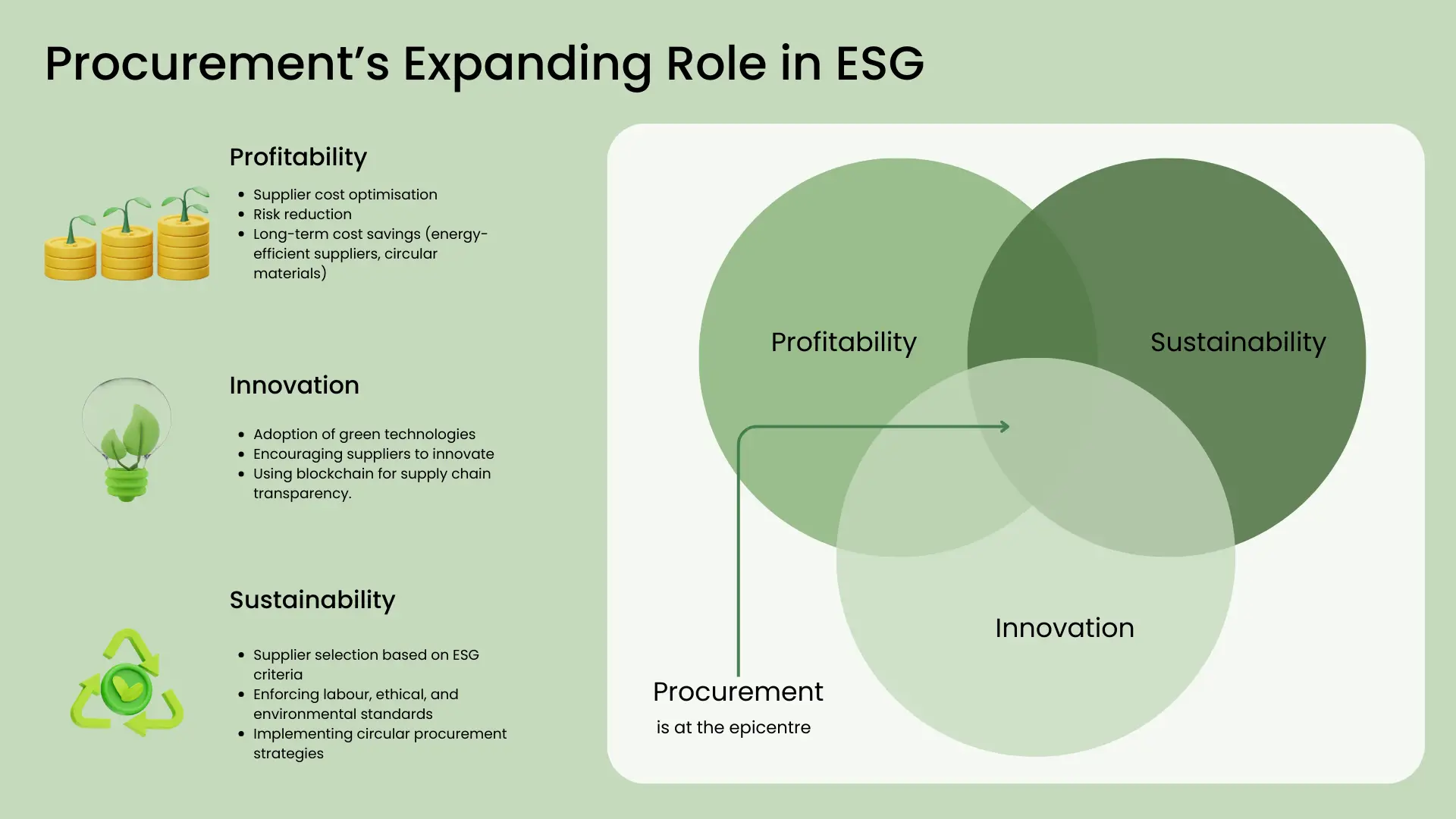

First off, procurement isn’t just about buying stuff anymore. (It never really was, but people are finally noticing.) Procurement teams today shape how products are made, how ethical supply chains are, and how companies meet their ambitious net-zero sustainability objectives.

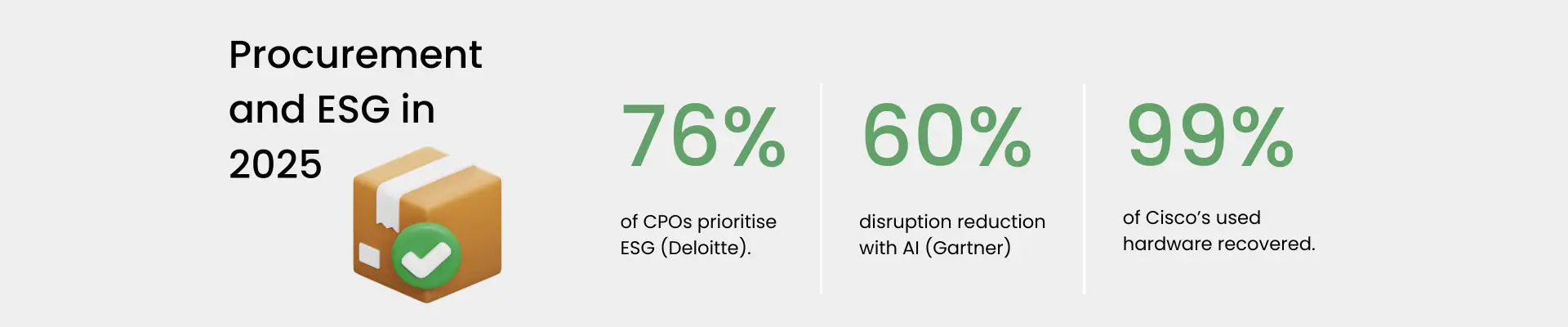

According to Deloitte’s 2024 Global CPO Survey, 76% of procurement leaders cited “driving ESG outcomes” as one of their top three priorities. Yet, only 28% said they had fully embedded ESG into their procurement decision-making.

Translation? There’s a huge opportunity — and a huge gap — waiting for bold procurement leaders to close.

“You can’t deliver on ESG promises if procurement isn’t leading the charge — it’s where dreams either die or take flight.”

— Peter Smith, author of Procurement with Purpose

The Electronics and Smart Manufacturing Challenge

Electronics and smart manufacturing come with their own “bonus level” of complexity.

Think:

- Conflict minerals (hello, cobalt and lithium)

- Energy-intensive production processes

- Rapid product obsolescence and e-waste issues

- Global supply chains with often-murky visibility

In this arena, sustainable procurement isn’t just a “nice-to-have.” It’s mission-critical. And leading companies are proving that it’s possible without tanking profitability.

Case in Point:

- Apple committed to becoming 100% carbon-neutral across its entire supply chain by 2030. Procurement teams are front and centre, driving sustainable supply transitions to clean energy.

- Flex, a major electronics manufacturer, has embedded circular economy principles into its procurement practices, working with suppliers to reduce waste and extend product life cycles.

If they can do it at scale, so can you — with the right strategies.

By 2030, 50% of global manufacturers aim to achieve zero waste-to-landfill through sustainable procurement practices (World Economic Forum, 2024).

Strategy #1: Rethink Cost Beyond the Price Tag

Too often, cost assessments in procurement are single-minded: cheapest quote wins. But ESG procurement means expanding the definition of “cost.”

Think bigger: What’s the cost of reputational damage if a supplier is caught violating labour standards? What’s the financial impact of a product recall due to non-compliance?

According to McKinsey, companies with strong ESG practices have lower cost of capital by up to 10% and show higher operational performance by about 3–5% over their peers.

So, next time you’re at a supplier negotiation, remember: cheap can be very expensive later.

Strategy #2: Build ESG into Supplier Scorecards

If you’re not evaluating your suppliers on ESG performance alongside cost and quality, you’re missing a trick.

Smart move: Create a supplier evaluation system that includes:

- Carbon footprint transparency

- Fair labour practices

- Circular product design

- Energy efficiency in production

Companies like Siemens now require all key suppliers to meet specific ESG standards, including setting their own science-based emission targets.

Bonus tip? Reward suppliers that lead the way. Preferential contracts or longer-term agreements can incentivize suppliers to invest in sustainability — a win-win.

Companies with strong ESG credentials reduce their cost of capital by up to 10% (McKinsey, 2024).

Strategy #3: Tech is Your Secret Weapon

You can’t manage what you can’t measure. Luckily, smart manufacturing is all about data, and procurement can get a serious edge by using:

- Blockchain to increase traceability

- AI to predict ESG risks in supplier networks

- IoT sensors to track environmental performance in real-time

A 2023 report by Gartner found that companies using AI in supply chain risk management reduced disruption impacts by 60%.

Translation: Technology isn’t replacing you; it’s upgrading you to Procurement 2.0.

Strategy #4: Go Circular, or Go Home

Linear supply chains (take-make-dispose) are so 1999. Circular procurement focuses on:

- Designing for longevity

- Refurbishing and remanufacturing

- Recycling critical materials

Smart manufacturers like Cisco have already shifted procurement policies toward circularity, helping to recover over 99% of used hardware.

Not only does this slash emissions and landfill waste, but it also reduces dependence on volatile raw material markets. Pretty sweet, right?

Expert Insights: What the Big Thinkers Say

As Peter Smith, author of Procurement with Purpose, cheekily puts it: “Procurement is where the rubber hits the road on ESG goals. You can’t greenwash a purchase order.”

And according to Lisa Martin, CPO at GSK, “Embedding ESG in procurement isn’t a sideline task. It’s fundamental to resilience, innovation, and future-proofing your supply chain.”

In short: procurement is the new power player.

Profit + Purpose = Procurement’s New Superpower

Closing Thoughts:

Sure, aligning ESG goals with profitability isn’t simple. But guess what? Neither was learning how to use a pipette in a chemistry lab or solder a tiny microchip under pressure.

Procurement professionals who crack this code will not just survive the future — they’ll shape it.

So here’s the real question:

Are you ready to be the procurement hero your company — and the planet — desperately needs?

The balance is tricky, but totally achievable. And trust us, it’s *so* much cooler than just saving a few cents on the next RFQ.

Game on.

Explore more related content

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Digital Product Passports for Small Appliances & Air Purifiers

Digital Product Passports for Small Appliances & Air Purifiers: A 2025–2027 Manufacturer Playbook From the Oxera...

Managing Sudden Demand Spikes: Scaling Challenges in Manufacturing

Managing Sudden Demand Spikes: Scaling Challenges in ManufacturingSourcing flexibility is crucial for supply chain...