Supplier Relationship Management: The Real Muscle Behind Lean Manufacturing

“Long-term supplier relationships are built on trust, communication, and shared improvement—not on transactional pricing.”— Institute for Supply Management (ISM)

The Lean Paradox: Efficiency Isn’t Enough

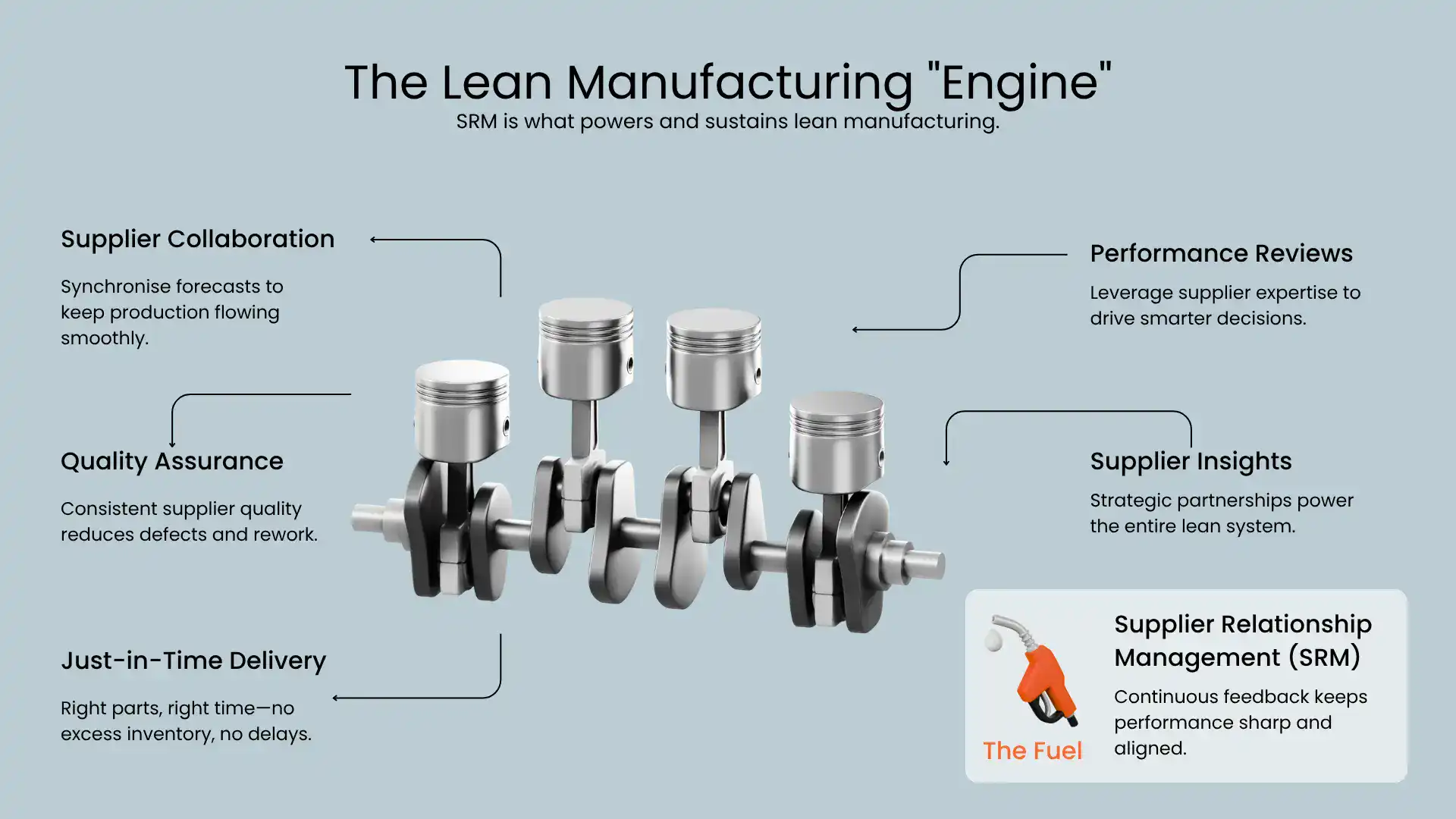

Lean manufacturing sounds brilliant in theory – simplify, streamline, and eliminate waste. But let’s get real: it hinges significantly on your suppliers. Supplier Relationship Management (SRM) solution is the backbone of genuinely effective lean manufacturing operations, offering substantial benefits when approached strategically.

SRM Defined: It’s a Partnership, Not Just Transactions

SRM is about nurturing strategic partnerships rather than merely managing transactional exchanges. True SRM moves beyond cost-driven relationships. Real supplier performance management means transparency, aligned incentives, and continuous improvement—no B2B fluff, just practical collaboration that pays off.

Mature SRM programs deliver 5-15% sustained cost savings beyond initial sourcing.

— The Hackett Group, Procurement Key Issues Study

Why Lean Manufacturing Needs SRM (Hint: You Can’t Do It Alone)

Lean principles like Just-In-Time (JIT) delivery and waste minimisation crumble without reliable supplier partnerships. If suppliers aren’t integrated into your lean strategies, you’re just rearranging deck chairs on a sinking ship.

- Just-in-time (JIT) Inventory: Effective SRM ensures timely deliveries, reducing costly inventory holding.

- Quality Assurance: Strong partnerships with suppliers ensure consistency in product quality, minimising defects and rework.

- Collaborative Innovation: Engaging suppliers early in product development promotes innovation and shared solutions to manufacturing challenges.

Research consistently demonstrates that manufacturers prioritising strong supplier relationships achieve greater flexibility, lower overall costs, and fewer operational disruptions.

Common SRM Mistakes You Might Be Making (And How to Fix Them)

While aiming for lean manufacturing, here’s where even the smartest procurement pros trip up:

- Poor Communication: Vague or infrequent communication can disrupt production schedules. Maintain regular, structured dialogues to align expectations.

- Ignoring Supplier Insights: Suppliers have invaluable frontline expertise. Involve them early in strategic decisions to benefit from their practical insights.

- Late Integration: Delayed supplier integration into lean processes often results in inefficiencies. Engage suppliers from the outset of your lean journey.

When suppliers participate in your strategic planning, you don’t merely react to problems—you proactively prevent them.

“Organisations with strong SRM report 33% higher supply chain agility during demand fluctuations.”— Gartner Supply Chain Research

Supplier Insights from Intretech: What Actually Works

At Intretech, we’ve witnessed firsthand how supplier collaboration accelerates lean manufacturing success:

- Joint Forecasting and Planning: Collaborative forecasting significantly streamlines supply chains, making lean practices genuinely achievable.

- Co-development Initiatives: Jointly developing products or refining processes with manufacturers enables both parties to share innovation benefits.

- Regular Performance Reviews: Structured reviews ensure mutual accountability and continuous performance improvement.

Intretech’s approach is straightforward: real lean success comes from supplier interaction that go deeper than cost negotiations. We’re talking genuine strategic alignment.

Measuring the Real Value of SRM in Lean Manufacturing

Effective SRM’s impact is both measurable and compelling. Metrics to assess SRM’s value include:

- Lower Inventory Costs: Lean operations mean holding less stock. Good SRM delivers the reliability to make it possible.

- Quality Gains: Consistent quality from suppliers directly reduces rework and improves efficiency.

- Greater Flexibility: Responsive suppliers make your entire operation more agile, helping you adapt quickly to market shifts.

Remember, lean manufacturing is about smarter, mutually beneficial partnerships that produce tangible results.

“The goal is not to squeeze your suppliers but to unlock mutual value.”

— Harvard Business Review

Leaner, Smarter, Stronger—Together

The success of lean manufacturing hinges heavily on strong supplier networks. When these relationships are built on trust, transparency, and aligned strategic goals, lean efficiency becomes second nature.

At Intretech, we understand this connection profoundly and we get it because we live it.

Effective Supplier Relationship Management isn’t optional—it’s essential for any business serious about lean manufacturing.

Ready to Enhance Your Lean Journey?

Connect with us at Intretech—we’d love to discuss how we can collaboratively drive your lean success forward.

Explore more related content

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive Advantage

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive AdvantageSupply chain disruptions now...

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...