Navigating NPI in 2025: How EVT to MP is Evolving in Today’s Global Manufacturing Landscape

“In product development, early collaboration beats late optimisation — every single time.”

— Dr. John O’Sullivan, VP Manufacturing Strategy, Flex

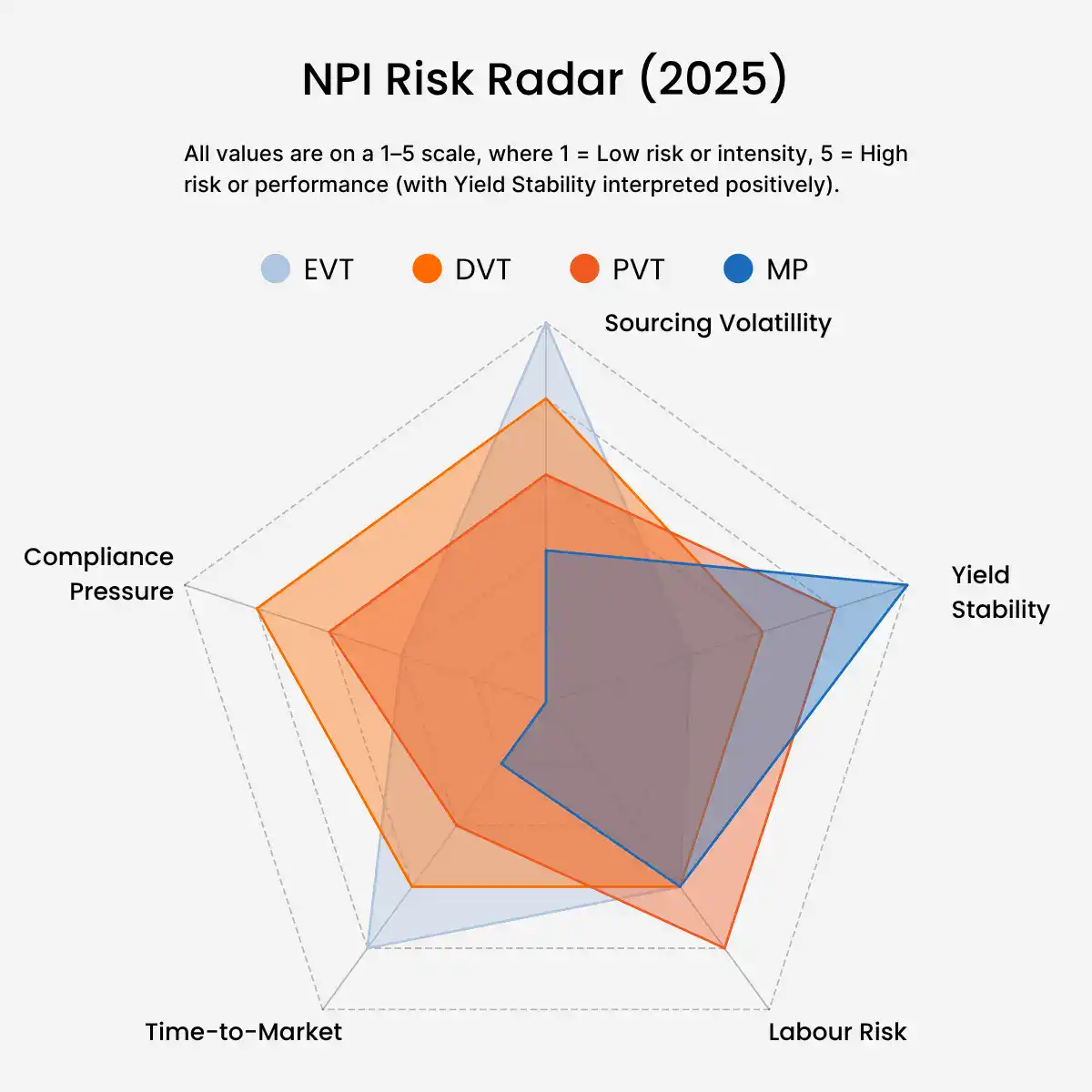

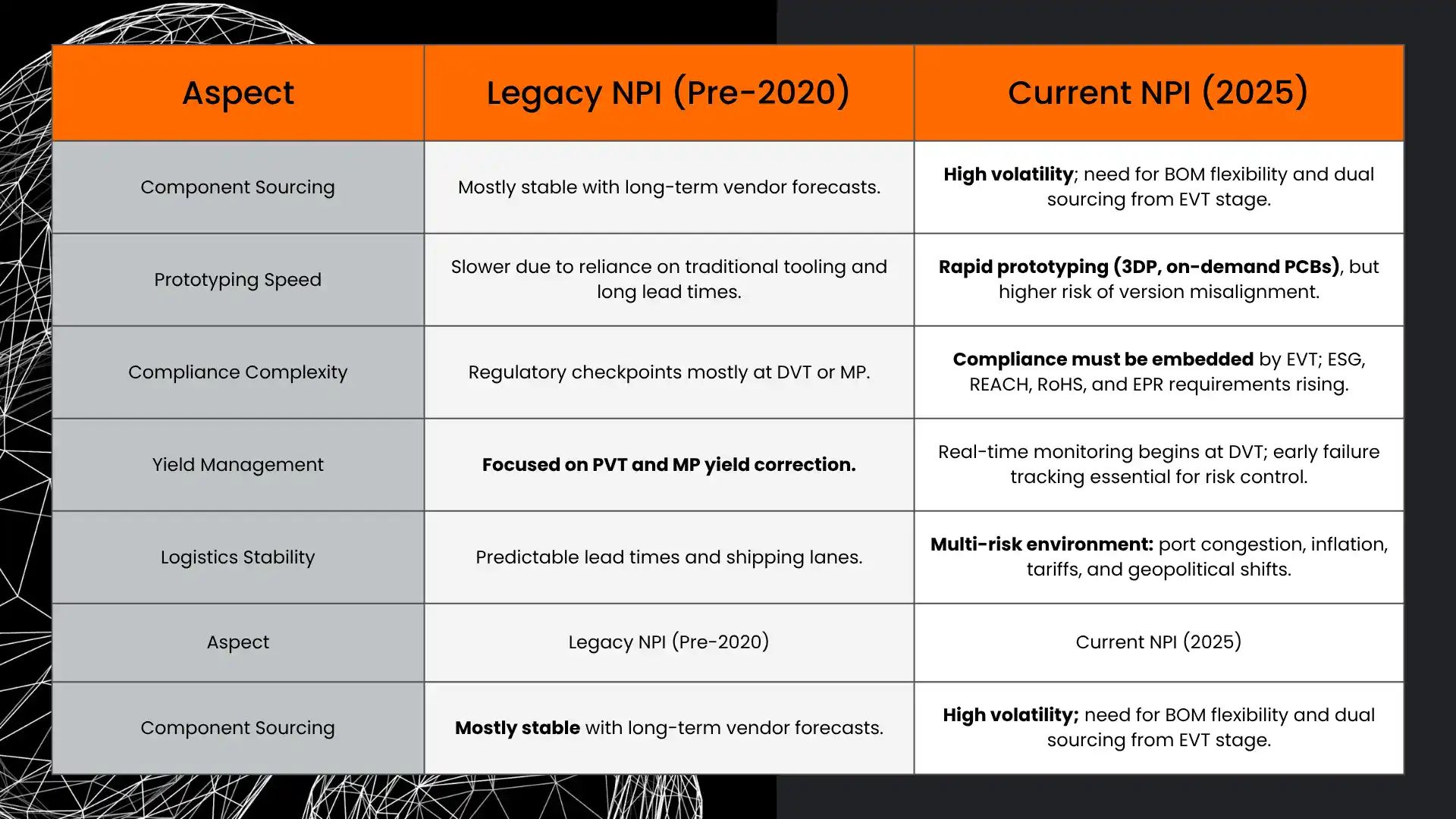

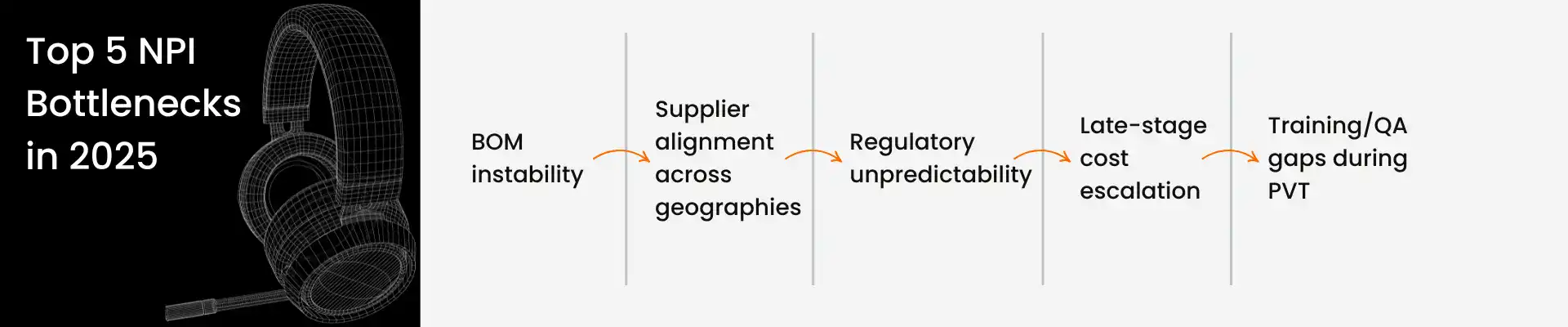

New product launch has long required some combination of technical validation and cross-functional coordination. The stakes are higher today, though. Supply chain volatility, parts shortages, inflationary pressures, and increasing compliance challenges are changing the manner in which manufacturers are handling New Product Introduction (NPI).

This handbook redefines the key NPI stages—Engineering Validation Testing (EVT), Design Validation Testing (DVT), Production Validation Testing (PVT), and Mass Production (MP)—through the filter of today’s global manufacturing realities. Whether you’re an engineer developing prototypes or a sourcing manager managing multi-vendor complexity, this new perspective is designed to provide clarity and strategic guidance.

Manufacturers that integrated their NPI stack (PLM + MES + ERP) improved launch success rates by 28%.

(Deloitte Future of Manufacturing, 2024)

Stage 1: EVT — Engineering Validation in the Era of Disruption

In the best of all worlds, EVT is when you verify the product’s basic functionality with close-to-final parts. But in the modern context, engineering teams have two more issues to deal with: component availability and prototyping nimbleness.

Current insight:

- Lead times on critical components (e.g. MCUs, sensors, power ICs) remain unpredictable. McKinsey (2023) reports only 31% of industrial leaders have confidence in being able to handle supply uncertainty.

- Rapid prototyping methodologies like on-demand PCB fabrication and additive manufacturing accelerate iteration but introduce new version control and consistency hazards.

Revised priorities:

- Build flexibility into your early-stage BOM.

- Utilise EVT as both a technical validation and supply chain risk assessment.

- Involve procurement early to identify high-risk components and potential alternate sources.

Catching a design flaw at DVT is 5–7x cheaper than fixing it at MP. (McKinsey Ops Survey, 2023)

Stage 2: DVT — Design Validation Under Cost and Compliance Constraints

DVT is where the designs are fixed, tool investment begins, and issues of compliance take center stage. During the recent years, two drivers have redesigned this stage: stricter global regulations and cost control needs.

Current insight:

- Regulatory worlds are shifting—RoHS 3, REACH, and extended producer responsibility legislation now affect material and packaging choices.

- Gartner (2024) found that only 29% of supply chain organizations believe they are well set to manage growing cost and compliance complexity.

Updated priorities:

- Conduct regulatory risk analysis in all target markets well in advance.

- Let tooling and fixtures support cost-effective, scalable assembly.

- Make sourcing and compliance checks prior to design freeze.

Step 3: PVT — Production Validation with Workforce and Yield Challenges

PVT is no longer just a matter of simulation of partial production. It is now the first real test of worldwide production feasibility against shortages of labor and geopolitical threats.

Current insight:

- McKinsey (2023) refers to skilled labor shortages as one of the top bottlenecks to world ramp-up capacity.

- Gartner (2024) states that only 8% of global supply chains can be classified as resilient, and fewer than 6% are antifragile.

Updated priorities:

- Begin training staff and SOP preparation before pilot runs.

- Leverage real-time first-pass yield and line balancing analytics.

- Deploy third-party quality partners to perform site scalability and vendor consistency audits.

The number of environmental regulatory changes affecting materials tripled between 2020 and 2023.

(European Commission, 2023)

Stage 4: MP — Mass Production in a Multi-Risk Environment

Mass production today has to contend with dynamic demand planning, unpredictable shipping costs, and digital traceability demands from regulators and customers.

Current insight:

- Transport disruption continues to be volatile. Procurement leaders ranked transport disruptions among the top 3 risks in Gartner’s 2024 Global Risk Radar.

- Traceability is a strategic necessity. 67% of the Gartner-polling executives indicate ESG and compliance transparency as board-level initiatives.

New priorities:

- Redundant design into logistics—two ports, staggered shipping schedules, backup warehouses.

- Use traceability tools in ERP systems to track all batches and component lot numbers.

- Monitor regulatory changes like the EU’s Carbon Border Adjustment Mechanism (CBAM) and US-China tariffs policy.

Strategic Takeaways for Engineering and Sourcing Leaders

- Resilience is the new efficiency. Don’t optimize for the optimal BOM—optimise for the most resilient supply path.

- NPI must be integrated globally. Tooling, test, and sourcing strategies must be aligned geographically.

- Compliance readiness isn’t optional. Environmental and regulatory changes can torpedo late-stage launches unless caught early.

- Let data drive decisions. Real-time yield, source, and logistics data must be part of every validation checkpoint.

- PVT is your safety net. Treat it as a launch dress rehearsal, not yet another checklist.

“You can’t retrofit traceability. If it’s not designed in from EVT, it becomes a liability at MP.”

— KPMG Industry 4.0 Insights, 2024

Conclusion: Reimagining NPI for 2025 and Beyond

The EVT–DVT–PVT–MP cycle is still a well-proven framework. But each phase now has to execute with an attitude of agility, traceability, and strategic vision.

McKinsey and Gartner data confirms what most manufacturing executives already intuitively know—resilience isn’t manufactured at scale; it starts in prototyping.

If you’re looking for a manufacturing partner with the operational maturity, digital capabilities, and global reach to support compliant, scalable NPI in 2025 and beyond—let’s get started. Let’s build smarter—gether.

Explore more related content

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive Advantage

Strategic Global Sourcing: How Companies Move from Cost Saving to Competitive AdvantageSupply chain disruptions now...

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...