Agentic AI in Manufacturing:

Why 2026 Is the Year AI Finally Starts Doing the Work

The global AI in manufacturing market is projected to grow into a multi-billion-dollar industry, driven by investments in smart automation, agentic AI, and autonomous operations. – Yahoo Finance

Manufacturing hasn’t had a data problem for a long time.

We’ve got sensors everywhere. Dashboards for everything. KPIs tracked down to the second decimal place. Most factories today can tell you exactly what went wrong, where it went wrong, and when it went wrong.

And then… we still wait for someone to act. That’s the gap agentic AI is starting to close.

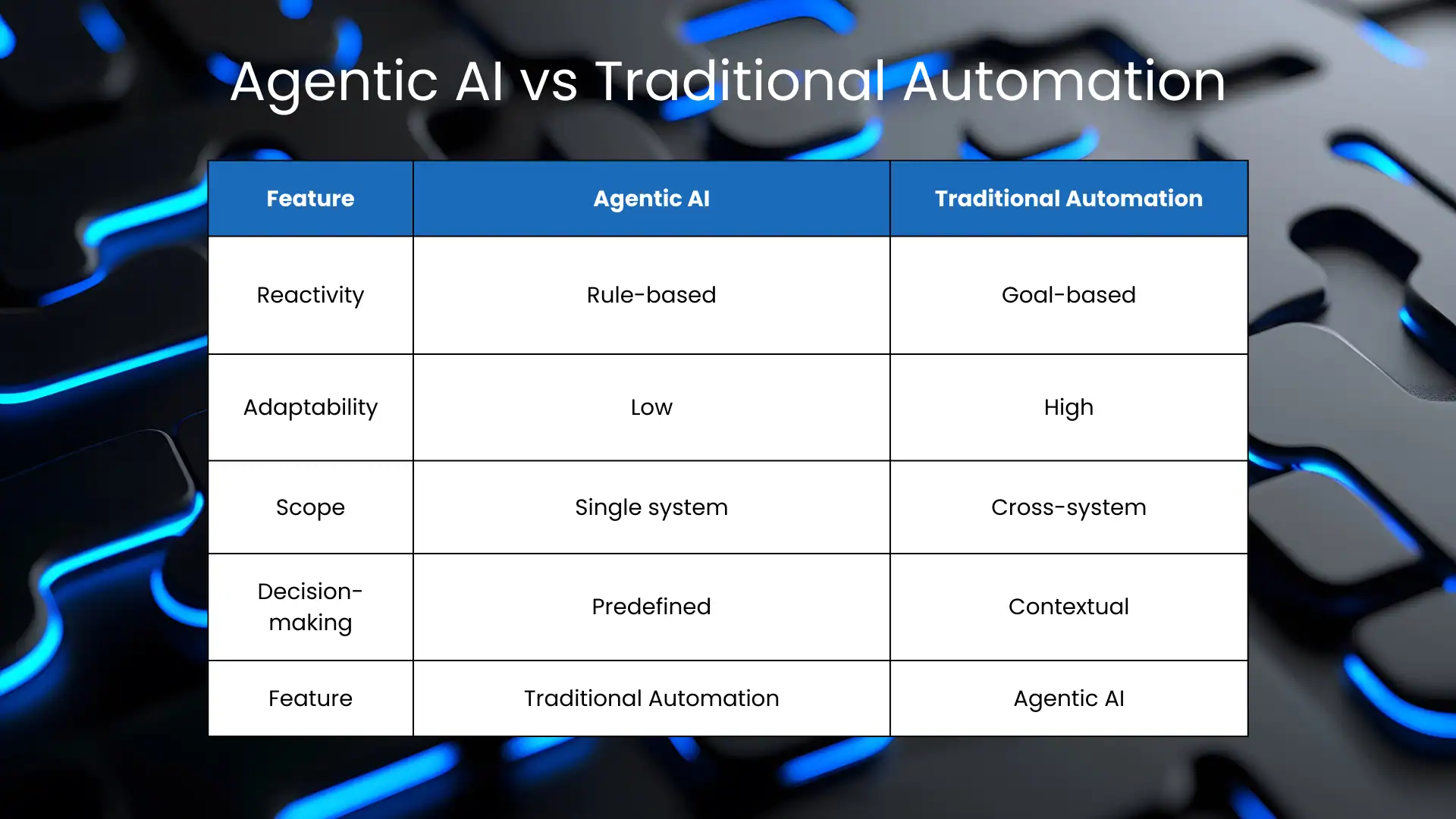

AI that once generated reports, alerts, or “insights” can now also take action, within defined limits, to keep production moving.

Agentic AI is the shift from “AI that reports” to “AI that acts.” Rather than a chatbot bolted onto an MES screen, we now have autonomous software agents that can observe, plan, and execute within guardrails; coordinating across quality, maintenance, scheduling, and supply. Gartner’s view is blunt: 40% of enterprise applications will include task-specific AI agents by the end of 2026 (up from <5% in 2025).

For engineers and manufacturing leaders, 2026 is the year this shifts from being a slide-deck concept and starts being an operating model.

By 2024, approximately 35% of manufacturing firms were already using AI technologies to improve predictive maintenance, quality control and supply chain management.

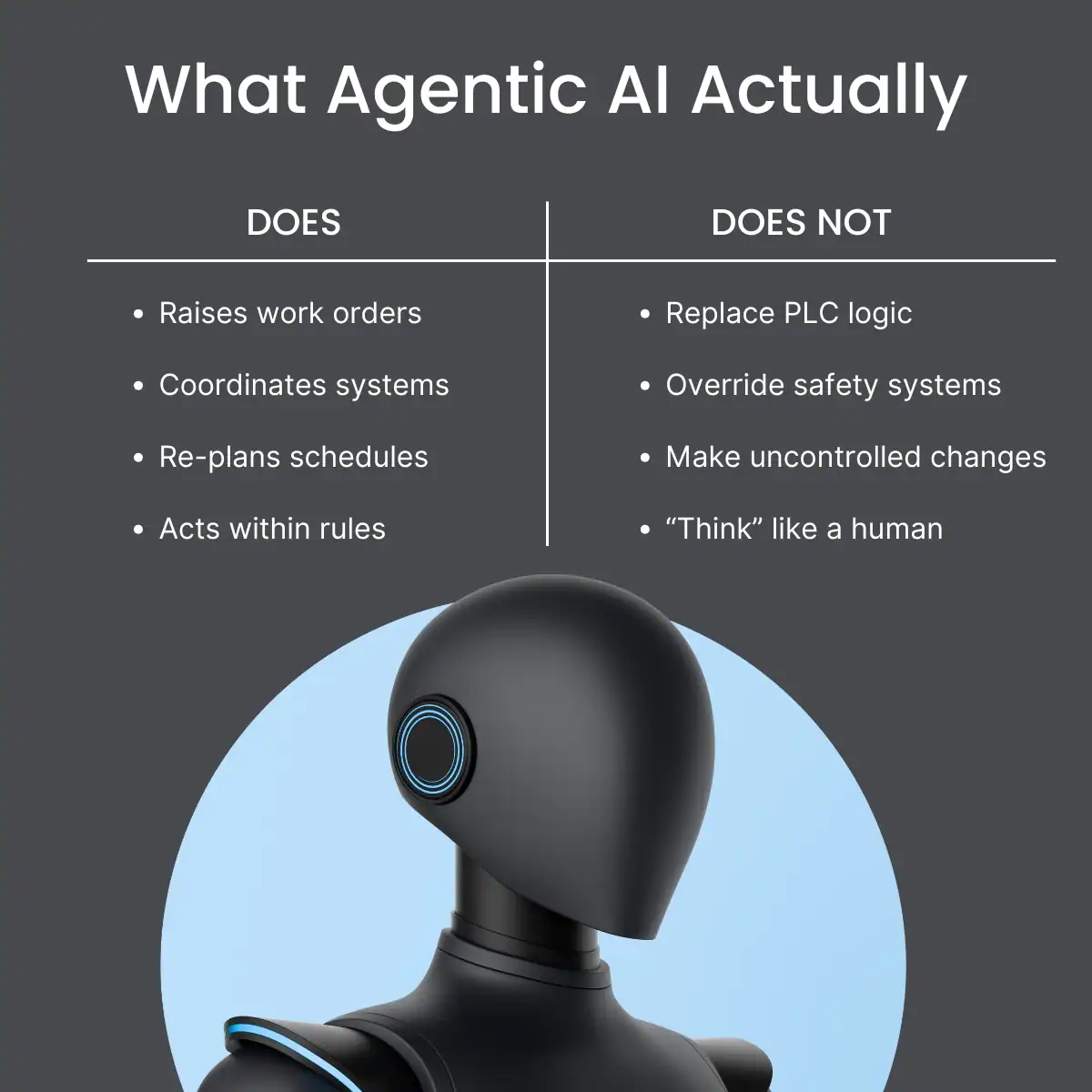

What “Agentic AI” Actually Means on the Shop Floor

Let’s de-hype this.

- Traditional analytics: “Line 3 is down.”

- Predictive AI: “Line 3 will likely fail in 12 hours.”

- Prescriptive AI: “Replace bearing X today.”

- Agentic AI: “I’ve created the work order, checked spares, booked a 20-minute window after the current batch, notified the supervisor, and updated the schedule.”

That last step is the difference.

Agentic AI combines sensing, reasoning, and execution. It works towards a goal (keep OEE high, reduce scrap, avoid downtime) and takes the steps needed to get there without waiting for a human to stitch systems together manually.

And yes, the industry is aware this can go wrong. Experts estimates that many early agentic AI projects will fail because teams apply it where it doesn’t belong or remove too many guardrails too fast.

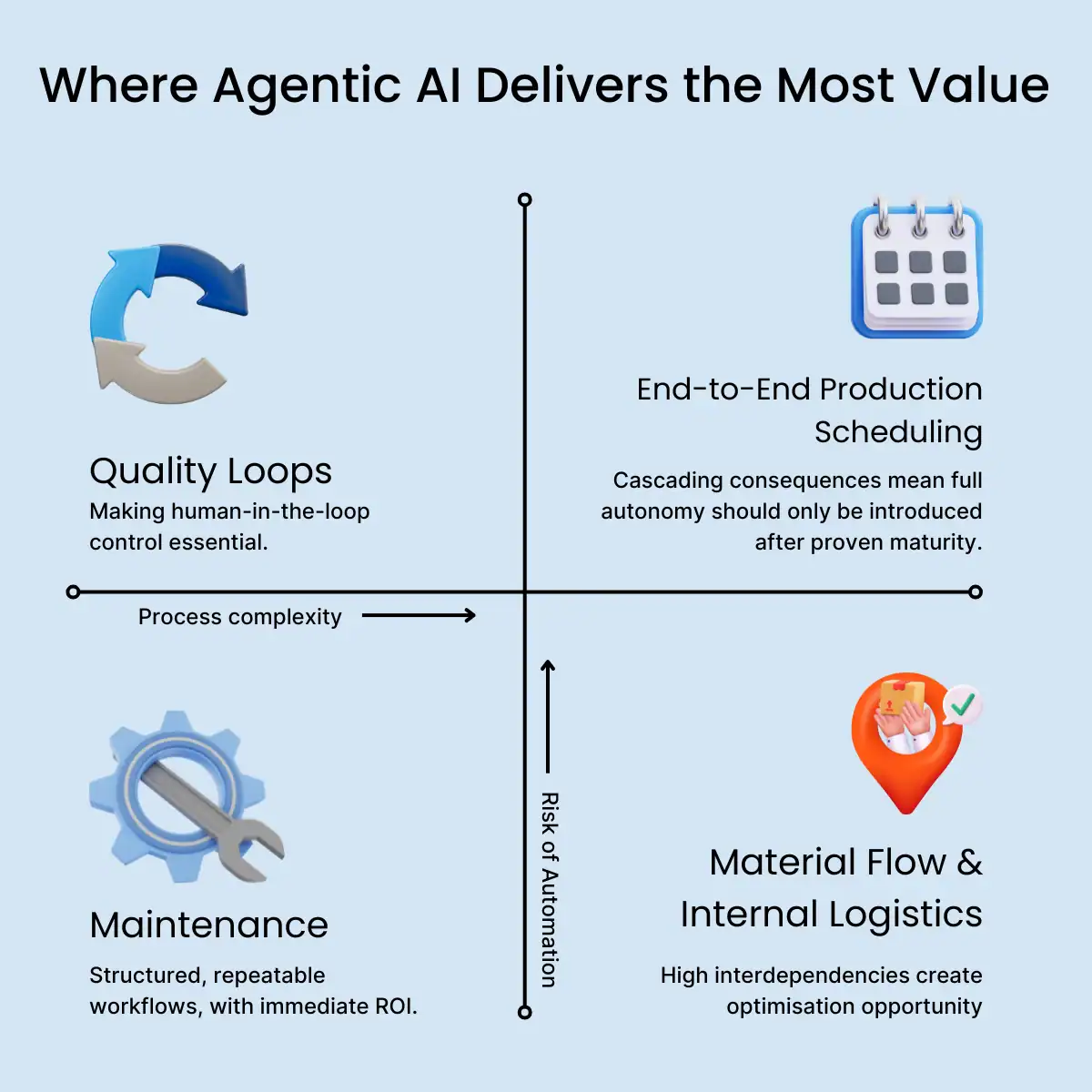

The Winning Use Cases in 2026

1) Maintenance Agents That Prevent Downtime

Predictive maintenance isn’t new. Getting it to actually change outcomes at scale is. Deloitte’s predictive maintenance position paper cites average impacts like 25% productivity increase, 70% reduction in breakdowns, and 25% lower maintenance costs when implemented effectively.

Agentic AI takes that next step: It initiates the full maintenance workflow (ticketing, spares allocation, scheduling, technician routing) with human approval where required.

2. Quality Control That Closes the Loop Faster

Cameras spot defects. Engineers investigate. Adjustments happen later. Agentic quality systems shorten that loop. They can:

- correlate them with process data,

- identify likely root causes,

- and propose (or apply) parameter changes.

This is where autonomy is valuable: shrinking the time between “issue detected” and “process corrected” from hours to minutes.

3. Scheduling That Accepts Reality

Production schedules break the moment real life shows up: machine delays, labour gaps, late deliveries.

Agentic scheduling systems continuously re-evaluate constraints and adjust plans in real time. More importantly, they can push approved changes into MES and ERP, not just suggest them.

This is where standards like ISA-95 matter. They give agentic systems a structured way to interact with manufacturing and business systems without causing chaos.

A 2025 Deloitte survey found that 80% of manufacturing executives plan to invest 20% or more of their improvement budgets in smart manufacturing initiatives, with agentic AI featured prominently.

How This Fits Into Real Factory Architecture

Agentic AI doesn’t replace PLCs. It doesn’t touch safety logic. And it shouldn’t be making millisecond decisions.

In a sensible setup, it sits above the control layer, working across systems that already exist:

- Sensors, PLCs, SCADA for raw signals

- MES, QMS, CMMS for execution

- ERP and supply chain systems for context

- An agent layer that coordinates actions

- Humans in the loop for approvals and exceptions

This is where standards like ISA-95 matter. ISA-95 defines models for manufacturing operations management and the data exchange between enterprise systems and control layers basically, the “language” your agent needs to act without causing chaos.

The Architecture Engineers Should Expect

A practical agentic stack in manufacturing typically looks like this:

- Signal layer: sensors, PLCs, SCADA, historians (time-series truth)

- Operations layer: MES/MOM, QMS, CMMS/EAM (work happens here)

- Business layer: ERP, SCM, customer demand signals (why we work)

- Agent orchestration: task-specific agents + policy engine + audit trail

- Human-in-the-loop controls: approvals, exceptions, escalation paths

The important engineering detail: agents don’t replace deterministic control. PLC logic stays deterministic. Safety stays safety. The agent lives above the control layer, interacting through defined interfaces, constraints, and permissions.

Think of it as adding an “autonomous coordinator” to Level ¾ ; without letting it freestyle in Level 0/1.

53% of UK manufacturers are already using AI on the factory floor, well above global adoption averages.” — Rockwell Automation / IT Pro (2025)

Guardrails: Autonomy Without Chaos

If you’re an engineer, you already know the failure modes:

a model makes a “reasonable” decision with incomplete context,

- changes one variable,

- breaks an interdependency,

- and QA becomes a crime scene.

So the guardrails are the product.

Cybersecurity guardrails: ISA/IEC 62443

The ISA/IEC 62443 series defines requirements and processes for securing industrial automation and control systems, bridging IT/OT and process safety with cybersecurity.

If an AI agent can trigger actions, it must sit inside a security model that supports segmentation, authentication, and least privilege.

AI risk guardrails: NIST AI RMF

NIST’s AI Risk Management Framework provides guidance to manage AI risks across design, development, deployment, and use especially relevant when generative and agentic systems are involved.

In practice: define what the agent is allowed to do, how it’s monitored, and what happens when it’s uncertain.

Operational guardrails: the “Autonomy Ladder”

Engineers should insist on staged autonomy:

- Suggest (recommend only)

- Assist (prepare actions for approval)

- Act in bounds (execute low-risk tasks automatically)

- Act broadly (rare; only when mature + audited)

If you jump to level 4 on day one, you’ve invented a new root-cause category.

Most agentic AI implementations today are early-stage experiments, and a significant share may be scrapped without clear business outcomes or constraints.” — Gartner Analyst Anushree Verma (2025)

What “Good” Looks Like in 2026

A strong agentic deployment in manufacturing will be boring in the best way:

- It has clear ownership (who is accountable for agent behaviour?).

- It has telemetry and audit logs (what actions happened, why, and when).

- It has fallback modes (manual control is a feature).

- It has measurable ROI tied to OEE, scrap, changeover time, and downtime.

And it targets the right tasks: repeatable processes with measurable outcomes and controlled action paths.

In 2026, What Is the Competitive Edge?

For years, manufacturers competed on machines, labour, and footprint. Now the differentiator is faster:

Who can sense, decide, and execute with the least latency and the most control?

Agentic AI is how you turn data into action at scale: faster maintenance response, tighter quality loops, smarter scheduling, and fewer “we saw it coming but didn’t act” incidents.

The factories that win in 2026 will have the best autonomy engineered, governed, secure, and relentlessly practical instead of data-filled dashboards.

Explore more related content

AI-Powered Robotics in Automotive: The Manufacturing Advantage No One Can Ignore

AI-Powered Robotics in Automotive: The Manufacturing Advantage No One Can Ignore“Dig into every industry, and you'll...

AI Hardware: The Next Frontier for Smart Manufacturing

AI Hardware: The Next Frontier for Smart Manufacturing 2025 has been a headline year for AI — not just in software,...

Why Passive Safety Matters for Automotive Businesses

Why Passive Safety Matters for Automotive BusinessesIn the competitive landscape of automobiles, driver safety is not...