Turnkey Product Development: Why Top Smart Home Brands Are Ditching Piecemeal Manufacturing

62% of smart home product delays stem from poor cross-vendor coordination. (McKinsey, 2023)

Today, forward-thinking smart home brands are making a hard pivot — toward turnkey product development. And no, it’s not just another buzzword slapped on a glossy pitch deck. It’s a strategic, bottom-line move that eliminates friction, accelerates time-to-market, and protects product quality from day one.

So why is everyone still clinging to piecemeal manufacturing like it’s gospel? Let’s break it down.

We thought using the best vendors in each category would give us an edge. Instead, we spent 40% of our budget fixing handoff issues.” – Head of Product, IoT Startup

The Old Way: Piecemeal = Pain

Here’s the traditional model: Design your smart thermostat in one place. Prototype your security camera somewhere else. Source sensors and modules from five suppliers. Assemble in a different time-zone. Coordinate it all while praying your project doesn’t turn into a case study in miscommunication.

Sound familiar?

Piecemeal might look flexible on paper, but it comes with hidden costs:

- Delayed timelines** due to misaligned handovers

- Quality issues** from poor DFM integration

- Scope creep** and spiralling costs

- Lack of accountability** when something breaks (and it will)

At some point, the “best-in-class” model starts looking more like “death by a thousand firmware updates.”

64% of brands using turnkey partners report higher product margins by the second launch. (Deloitte, 2024)

The Turnkey Shift: One Partner, Full Stack

Turnkey product development flips that mess on its head. You get one experienced partner who owns the whole stack:

- Industrial + mechanical design

- Embedded systems + wireless connectivity

- App and cloud integration

- Prototyping and user testing

- Tooling

- Mass production

- Quality assurance

- Supply chain management

One partner. One team. One shared goal.

It’s not just more efficient. It’s more *aligned*. Every decision, every trade-off, every iteration happens inside one ecosystem. No more guesswork. No more “lost in translation” moments between app developers and hardware engineers.

Is Turnkey More Expensive? Not If You Like Your Margins

Some execs still flinch at the idea. “Isn’t turnkey more expensive?”

Let’s reframe that: What does *delay* cost you? What about a missed product launch window just before the holiday rush? Or a critical bug in your smart lock firmware caught too late?

Turnkey isn’t about upfront savings. It’s about total lifecycle ROI:

- Faster to market = more time selling

- Fewer surprises = less firefighting

- Better integration = higher reliability = fewer returns

Turns out, *consolidation* is the most underrated innovation strategy in your smart home roadmap.

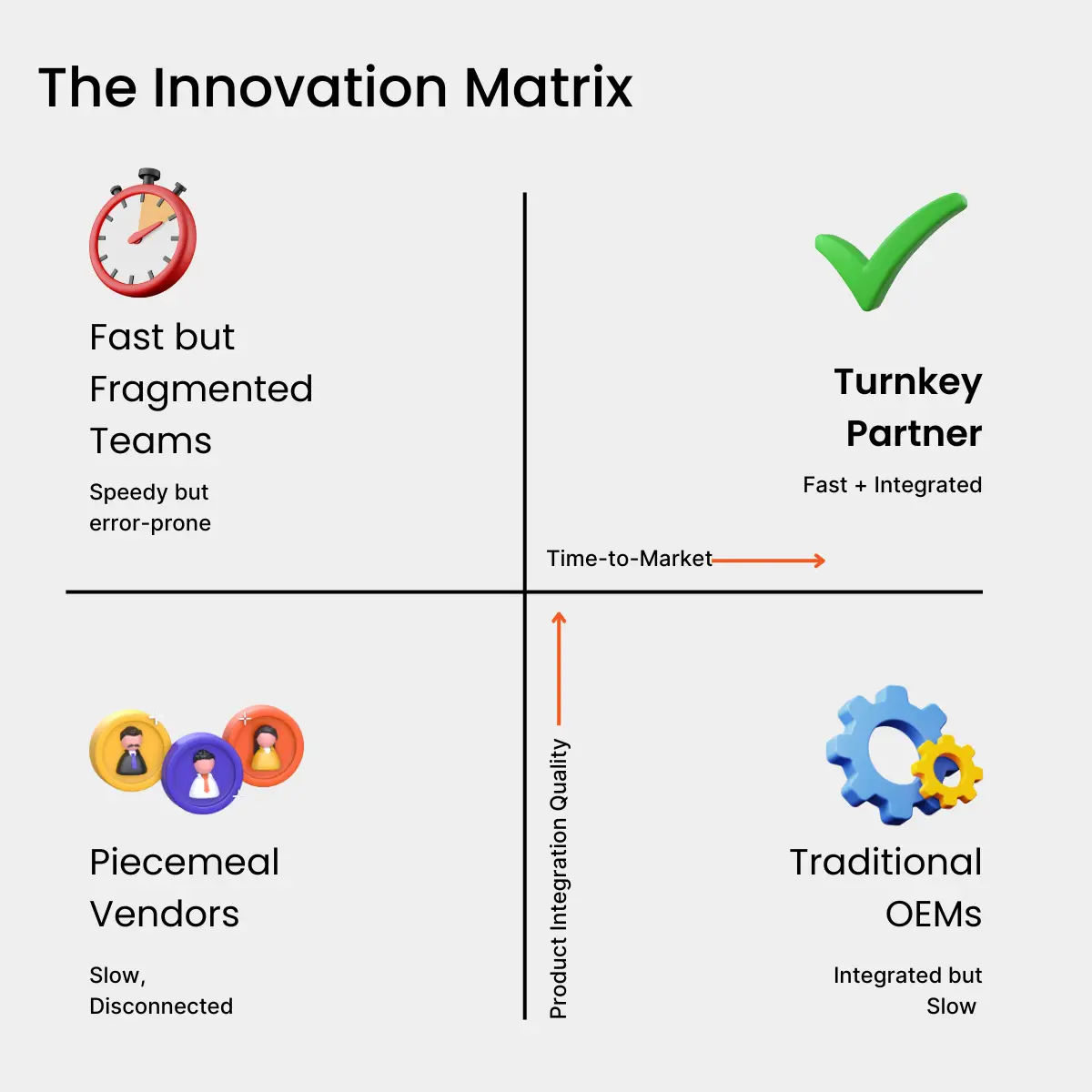

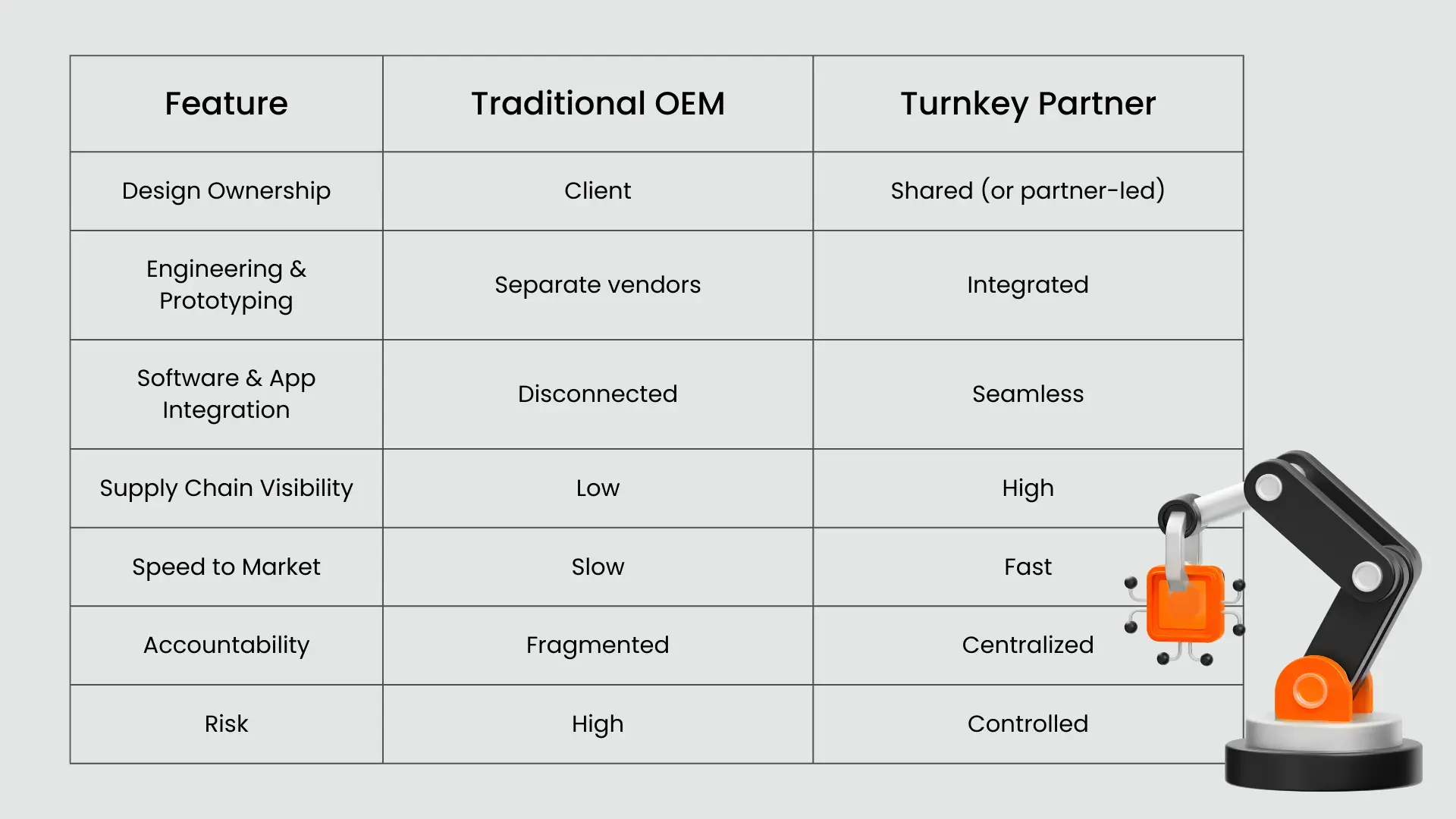

The OEM vs Turnkey Matrix (Because We Know You Love a Table)

“You don’t need more partners. You need the right one — who can do it all.” – Director of Engineering, HomeTech Co.

Still Piecing It Together? You’re Already Behind.

Smart home consumers expect sleek, seamless, and secure experiences — and they expect them yesterday. Brands that cling to the piecemeal model are building with legacy tools in a post-legacy world.

If you’re still juggling vendors, you’re leaving speed, quality, and margin on the table.

Let’s build something smarter. Together.

Contact us about Intretech’s turnkey smart home solutions.

Explore more related content

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply Chains

Critical Minerals, Critical Thinking: Building Resilient Electronics Supply ChainsThe global economy is expected to...

Cybersecurity for Smart Factories: A 2025 Playbook for OT Resilience

Cybersecurity for Smart Factories: A 2025 Playbook for OT ResilienceWhy "smart" now means "secure" or not at all Smart...

Digital Product Passports for Small Appliances & Air Purifiers

Digital Product Passports for Small Appliances & Air Purifiers: A 2025–2027 Manufacturer Playbook From the Oxera...